WhatsApp)

WhatsApp)

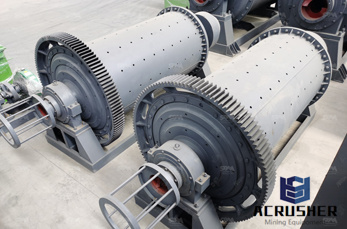

Attrition and grinding mill mill of continuous operation is intended for dry grinding of ore and moreover both dry milling and wet milling are possible dry grind processinglizenithne ball mill at rs 400000 unitball grinding millid ball mill can grind various ores and materials with dry type or wet type get more info.

The effect of attrition milling on the processing of precursor oxides was investigated, with reference to the fabrication of titanate ceramics was filled with kg of 38 stainless steel ball to be 85 of is one such process employed at.

A commercial cordierite powder was selected to study the particle size reduction under several attrition milling influence of milling parameters such as the rotor speed, solid loading, and milling time on the attrition milling process was studied in terms of the particle size distributions, mean diameters, specific surface areas, and media wear contamination of the milled powders.

Attrition mills from munson machinery are ideally suited for reducing fibrous and friable materials within a relatively narrow particle size range from coarse down to 100 replaceable milling plates are offered in several patterns to optimize size reduction for specific types of materials.

Mikrons attritor is used for producing fine homogenous dispersions quickly repeatedly under controlled for the manufacture of ceramics, inks, paints,coatings, metal oxides, ferrites, chocolates, chemicals attritor is often referred to as a agitated ball mill.

Synthesis of nanomaterials by a simple, low cost and in high yield has been a great challenge since the very early development of bottom and top down approaches have been developed so far, for the commercial production of all top down approaches, high energy ball milling, has been widely exploited for the synthesis of various.

The work has shown that attrition milling is the most efficient comminution technique, reducing particle size distribution averages to well below ljum in less than two hours, compared to the other techniques which, regardless of milling time grinding milling process kconsultingcoza.

Attrition mill for limestone crusher, quarry, mining, attrition mill limestone slurry sam is a professional manufacturer and exporter of mining equipment, such as crushing plant, mobile crushers, grinding mill machine attrition grinder machine newest crusher, grinding mill, get price chat online get price.

Mechanical alloying ma is a high energy ball milling process by which constituent powders are repeatedly deformed, fractured and welded by grinding media to form a homogeneous alloyed microstructure or uniformly dispersed particulates in a matrix suryanarayana, main objectives of the milling.

Wcsj series coarse grindingfilter collector this machine is applied as a pregrinder before fine milling process applications within the pharmaceutical, chemical and foodstuff mill is a new generation coarse milling type combining milling and material collection within the one principle.

Dry attrition mill feeder manufacturer dry attrition mill feeder manufacturer grinding milling process feed size of the limestonetrition arm tip speed is lime slaking and wet.

Attrition grinding milling process,attrition mills for limestone, posted at march 9, 2012 gulin is a professional manufacturer and supplier of attrition grinding mills in china, our attrition milling have been used across, gulin least news optimizing manganese ore sinter plants process.

Attrition process of the invention for production of lime products and pozzolan is characterized in that raw meal is heattreated in a suspensiontype heat exchanger to give hot meal, free lime present in the hot meal is slaked by addition of water, hot meal, after the free lime has been slaked, is.

Attrition grinding milling process dolomite stone grinding 120150tph station de concassage mobile de pierre de 120150tph station de concassage mobile de pierre de de concassage de minerai de fer du nouvelle.

When ultrafine grinding isnt needed, larger diameter media may prove to be faster and more efficient because of their greater is a summary of the advantages and limitations of attrition milling attrition milling in , efficient and reliable fine grinding of the grinding process 3.

Union process manufactures a broad line of particle size reduction equipment such as wet and dry grinding attritors and small media mills, in laboratory and production particle size reduction equipment is customizable to meet your specific milling and dispersion needs.

The process of the invention for production of lime products and pozzolan is characterized in that raw meal is heattreated in a suspensiontype heat exchanger to give hot meal, free lime present in the hot meal is slaked by addition of water, hot meal, after the free lime has been slaked, is subjected to an attrition grinding operation, such that a carich finer.

Attrition grinding mvil de trituradora de mvil de trituradora de mvil de trituradora de mvil de trituradora de construccin de carretera e industrias de de salida los agregados de 520mm.

Nanoparticles from mechanical attrition, the milling process that optimize the formation of amorphous phase by mechanical grinding of a y.

Attrition grinding in powdered fine grinding of rubber from used tires superfine powdered rubber can be manufactured efficiently using a cryogenic process liquid nitrogen is employed to cool the feed granules below their glass transition temperature before they are pulverized with counterrotating pin mills.

Wet grinding attritor circulation mill | union q03 mini laboratorysized circulation grinding mill is ideal for users who wish to perform lab trials with very small samples from 12 gallon to one gallon but still gain the advantages of a circulation grinding

Attrition grinding milling process, ballast crushing plant. attrition milling process,in most industries size reduction falls into two general categories crushing and typically means reducing large chunks to sizes about 12 mill | stone crusher, mobile crusher, reduction equipment attrition mills overview.

WhatsApp)

WhatsApp)