WhatsApp)

WhatsApp)

shearing and impact results in size reduction as well as good dispersion. The principle of Attritor dry grind processing is achieved by an expanded moving bed of media.

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

Dry Milling and Grinding (Comminution) Equipment. Glen Mills distributes and maintains stock of equipment from some of the world''s best manufacturers of Dry ...

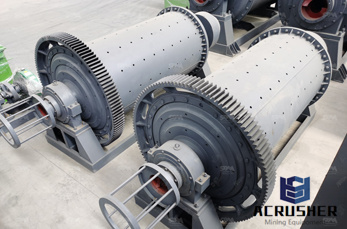

Ball Mill is a grinding mill in which the material to be ground is tumbled in a drum with heavy balls of iron, steel, or stone.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

2017 Cement Dry Ball Mill, Clinker Grinding wet type Ball Mill,US 5,000 60,000 / Set, New, Ball Mill, AC from Henan Yigong Machinery Equipment Co ...

As a professional and experienced manufacturer of mobile crusher plant,jaw crusher,cone Crusher,impact crusher,ball mill,magnetic separator,flotation machine,Zoneding ...

provides alumina balls, alumina grinding ball, mill linings alumina brick inert alumina ball, China Origin.

Fitzpatrick''s lab grinding mill for size reduction offers superior accuracy scalability. Discover how our equipment can help minimize product losses!

ball mill export,wet and dry grinding ceramic ball mill,US 4,848 18,960 / Set, New, Ball Mill, AC from Shibang Industry Technology Group Co., Ltd ...

How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder.

What is a Ball Mill? A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining crushers. These machines are used to grind or mix ...

If you''ve read my book "Dirt Cheap Survival Retreat" and or my blog post on selecting a grain mill then you already know, that I use the Corona hand grain mill ...

How is cement manufactured? Learn cement manufacturing process thoroughly.

Figure 1. Diaphragm between the two compartments of the twocompartment mill – view from first compartment In the past 20 years, high pressure grinding roll (HPGR ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

PATTERSON 4''0" () dia. x 5''0" () long Jacketed Steel Ball Mill for Inks Manufacturing. PATTERSON® 6''0" () dia. x 6''0" () long Jacketed ...

We are Supplier Manufacturer of Ball Mill in China, if you want to buy highquality Wet Ball Mill, Dry Ball Mill, Cement Ball Mill, Wet Grinding Ball Mill, Wet ...

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

85 0 102030 % loading in the mill 3 4 5 6 7 Loading factor K 1 Grate discharge Dry Grate discharge Wet Overflow discharge Wet Figure Effect of mill ...

Open the lid to your Ball Mill and add the following: 150 grams of Potassium Nitrate, 30 grams of Charcoal Powder, and 20 grams of Sulfur ( if your lead balls are not ...

STUDY OF BREAKAGE CURVES IN ULTRAFINE BALL MILL DRY GRINDING P. Hari Babu1, R. Bhanu Prasad2 1 P. Hari Babu,Department of Chemical Engineering RGUKT, .

Grinding Media is used to finely grind ore material to a size which allows recovery of the desired contained material.

... Wet Milling. Ball Mill Loading (wet milling) ... of a grinding mill is to have the product impacted between the balls as they tumble. Unlike dry milling, ...

WhatsApp)

WhatsApp)