WhatsApp)

WhatsApp)

The procedure by which a sample is drawn is critical to the uppermost configuration on figure 3 is a highpressure zone where a ball valve or needle valve is installed and the outlet is fitted with a piece of stainless steel helical tubing the purpose of the tubing is to reduce the pressure of the fluid to a safe level before it enters the

Safe work procedure checklist 1 preoperation ensure no sliptrip hazards are present in workspaces and walkways locate and ensure you are familiar with the operation of the onoff starter and estop if fitted do not leave equipment on top of the machine check that machine guards are in position where applicablesuitable

Milling machines require special safety precautions while being used these are in addition to those safety precautions described in chapter 1 do not make contact with the revolving cutter place a wooden pad or suitable cover over the table surface to protect it from possible damage use the buddy system when moving heavy attachments

The mixing process for black powder is just as important as the formula black powder must be made in a ball mill to work properly a ball mill is a rotating drum with dozens of lead balls inside the 3 chemicals are loaded into the ball mill along with the lead balls sealed shut and allowed to rotate for anywhere between 1 hour and 24 hours

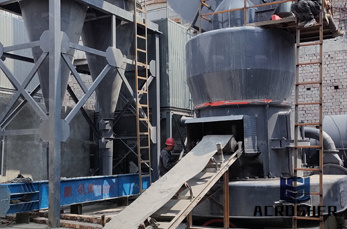

Safe work procedure for cement ball mill maintenance ball mill safe procedure ball mill safe job procedure safety glasses must be worn at all times in work areas safe work procedure for cement ball mill maintenance cement report chat now ball mill safe procedure henan mining heavy machinery co ltd if you want to know

1 overview of fdas animal feed safety system afss july 2019 feed safety background in 1906 congress passed the pure food and drug act giving the food and drug

Grinding in ball mills modeling and process control a procedure to determine penggerusan dengan ball mill replika menghasilkan indeks kebundaran 027 dengan bola penggerus keramik

The art of sharing andimagination home about us services grinding software consultancy training courses calculators online

Safe coal handling practices are designed to ensure that the fuel remains intact throughout its journey three riley power doubleended ball tube mills each mill can provide 65 tons per hour of pulverised coal to the boiler or a total of 195 tons per hour per boiler

Operating procedure for ball miller note internal timer has been modified to time for 9999 minutes extended time this ball mill was designed to run 15 minutes average time the original total time was 999 minutes maximum now it is 9999 minutes ie 160 hours to operate longer times two cooling fans have been installed and an

Procedure reference version effective date review date page number date printed whs sop 20 10 1 sop 20 feed mill roller mill operation servicing do not proceed in this operation unless appropriately instructed in its safe use and operation and permission to operate has been given

Of the individual to carry out all steps of the lockout procedure and inform the crew when it is safe to work on the equipment additionally the designated individual shall not remove a crew lock until it has been veri ed that all close and tag the ball valves before each tank push and lock out dump valves numbers 4 and 5 lock out the

Apr 11 2015 sop for ball mill in ppt 1 binq mining equipment sop for ball mill in ppt ball mill motion ppt ball mill presentation ppt ball mill grinding machine ppt construction of ball mill ppt ppt ball mill seminar ball mill grinding performance ppt

Ball mill and grinding circuit preparation for startup the following items must be checked before the equipment in the grinding circuit is started check the ore slot feeder for obstruction or hangups check the ball mill belt feeder for undue buildup of material check oil level in ball mill lube oil tanks also check grease level in the mill ring gear spray lube drum ensure that the

For its extensive practical experience 911 metallurgist has a clear understanding of what successful mineral processing engineering is and how to go about achieving goal is the production of a material that is marketable and returns you and your investors sustainable revenues

Feb 29 2020 a standard operating procedure sop is a document consisting of stepbystep information on how to execute a task an existing sop may need to just be modified and updated or you may be in a scenario where you have to write one from scratch it sounds daunting but its really just a checklist see step 1 to get the ball rolling

The extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and therefore short grinding times the pm 400 is a robust floor model with 4 grinding stations you may also be interested in the high energy ball mill emax an entirely new type of mill for high energy input the unique combination of high

Hammer mill standard operating procedures 1 hammer mill must not be operated solo at least two workers must be present when the mill is in use operators must wear eye and hearing protection as well as nuisance dust masks at all times when operating the mill operators must inform project leader when mill will be used 2

Safe interventions take place compound open mill mixing but also warming of premixed compound known as warming or cracker m ills or for cooling compound mixed in an internal mixer known as dump mills the main mechanical hazard is the nip between the main mill rolls in forward and reverse motion depending on

Achieving the desired particles via ball mill is a research project the project depends on the material grinding time speed and combination of grinding jar and quantitysize of milling ball it is your responsibility to find the best milling procedure based on your material across international offers paid sample testing prior purchase

The emax is an entirely new type of ball mill which was specifically designed by retsch for high energy milling the impressive speed of 2000 min1 so far unrivaled in a ball mill in combination with the special grinding jar design generates a vast amount of size reduction energy thanks to the new liquid cooling system excess thermal

WhatsApp)

WhatsApp)