WhatsApp)

WhatsApp)

Make a ball mill in 5 minutes this is for all the pyro nuts that i came across on instructables this can be used to grind chemicals to a very fine grain or to polish says a ball mill is a type of grinder used to grind materials into extremely fine powder for use i

Feb 17 2020 the channels arent simply straight cuts with a ball mill but curve in and out of the rotor hopefully that feature is apparent in the pictures how would i cut this without a very complicated and unreliable setup if so then you could set up a final machining step using a rotary table and the proverbial lollypop cutter but that

Jun 14 2018 below is the writeup of how a ball mill works is used to crush ore and an explanation regarding its effectiveness in gold mining the purpose of milling first of all in order to get the best out of how this particular equipment is used it is important to get acquainted with knowledge on what it is and is made of hence a mill is a piece

With lengths up to 6 inches harvey tool long length reduced shank carbide end mills can be chucked at any depth in stock same day shipping

Iqs directory implements a thorough list of ball mill manufacturers and suppliers utilize our listing to examine and sort top ball mill manufacturers with previews of ads and detailed descriptions of each product any ball mill company can design engineer and manufacture ball mills to meet your companies specific qualifications

Ball mills are among the most variable and effective tools when it comes to size reduction of hard brittle or fibrous materials the variety of grinding modes usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications

Grizzly industrial inc is a national retail and internet company providing a wide variety of highquality woodworking and metalworking machinery power tools hand tools and accessories by selling directly to end users we provide the best quality products at the best price to professionals and hobbyists

Minted ball mill steel balls is steel iron and other electric furnace heated up charge use to make the charge sufficiently melted add the amount of precious metal alloys to charge the melting furnace in the process of chemical ingredients quenched until the hot metal temperature above 1550 and meet the technical requirements after passing the

Aug 11 2007 learn how to build a ball mill for grinding solids into fine powders commercial ball mills can cost more than 100 but with this tutorial youll be able to make one that works just as well for no more than 30 ball mills can be used to grind ceramic material crystalline compounds and even some metals i used a direct drive set up

Mar 29 2019 ball mills are a special instrument used to break up hard solids into a fine powder they are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance into powder ceramic material crystalline compounds and even some metals can be ground up using a ball mill

Ball milling shell building cutters punches case formers rebel upgraded complete setup w 35lb lead 74500 74500 ball mill nut wrench 3400 8450 304 stainless steel 12 4500 22500 4500 22500 5lb lead ball mill media 3500 3500 10 lb lead ball mill media 6000 6000 35 lbs bulk lead milling media

Metallurgical contentball mill maintenance manualon mill installation and maintenanceball mill concrete foundationsgrinding mill foundationgroutingball mill sole plate am sure your ball mill is considered the finest possible grinding mill available as such you will find it is designed and constructed according to heavy duty specifications

New and used ball mills for sale savona equipment is a new and used ball mill supplier worldwidea ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sintering

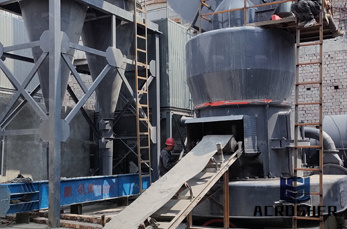

Ball mill set up ball mill set up grinder machine china grinding ball mill for sale view ball mill grinder machine china grinding ball mill for saleus 2600 115000 set new ball the raw materials of our wet ball mill grinding up to national standard

Ball milling is suggested as a novel method for enhancing filler dispersion in different matrices that is environmentally and economically sustainable 85 it is a solidstate mixing of powders usually performed with ball mills which enables intimate mixing of

Ball mills can be used to further break down or refine a single material or you can place multiple materials into a ball mill jar to mix as you pulverize this is a very common industrial solution for mixing glazes that require the smallest of mesh sizes ball mills basically function like a mortar and pestle but on a much larger scale

With more than 100 years of experience in ball mill technology metsos ball mills are designed for long life and minimum maintenance they grind ores and other materials typically to 35 mesh or finer in a variety of applications both in open or closed circuits

116 of over 2000 results for 3 stars up ball mill skip to main search results amazon prime eligible for free shipping hhip 6 piece high speed steel m2 ball nose end mill set 4flute 18 12 size range 47 out of 5 stars 11 5658 56 58 get it as soon as tue oct 29

This mill is going to come in really handy for lots of future projects i hope this page gives helpful ideas to anyone in need of a ball mill they are quick easy and cheap to build yourself i need to add a disclaimer here for anyone thinking of using this sort of ball mill for milling gunpowder or other flammable or explosive powders

These sets contain multiple carbide ball end mills in a range of sizes ball end mills have a rounded nose and create a roundbottomed groove in milling tasks also known as ballnose end mills they are rotated against a workpiece to make roundbottomed slots and pockets or mill

Ball mills steel ball mills lined ball mills particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800s the basic construction of a ball mill is a cylindrical container with journals at its axis

Ball mills have been the primary piece of machinery in traditional hard rock circuits for 100 years they are proven workhorses with discharge mesh sizes from 40m to 200m use of a ball mill is the best choice when long term stationary milling can be justified by an operation

Msc offers a wide range of end mill sets whether its for general purpose of aggressive machining msc has several styles including ball end corner rounding and square end mills for every application

WhatsApp)

WhatsApp)