WhatsApp)

WhatsApp)

NSK Europe | Bearings leading manufacturers of bearings. Ball Bearings, roller bearings, wheel bearings, automotive bearings, bearing units, hub bearings, steering ...

Cement history. Throughout history, cementing materials have played a vital role and were used widely in the ancient world. The Egyptians used calcined gypsum as a ...

Convert Waste to Energy with Methane Production Learn how to convert manure and garbage to energy using this smallscale methane producing plant.

Extreme Pressure Grease Other Industrial Greases LE''s industrial greases: General purpose bearing grease to extreme pressure grease. Lubrication Engineers offers a ...

Planetary Ball Mills are used wherever the highest degree of fineness is required. Powerful and quick grinding down to nano range. Read more.

industrial case study: the cement industry calmac study id: final report prepared for pacific gas and electric company san francisco, california

Wall and floor tile used for interior and exterior decoration belongs to a class of ceramics known as whitewares. The production of tile dates back to ancient times ...

About Gulin. Looking for Information about Gulin? Visit for company news and careers as well as information about Gulin''s entire portfolio ...

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

Vertical roller mills (VRM) can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal ...

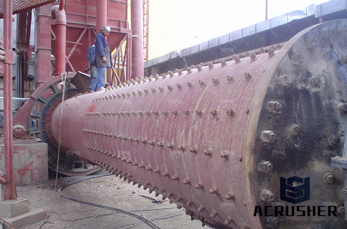

Ball Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are commonly mined using dredges, from lakes ...

strengthening and have a certain strength. Two, thermal bonding nonwoven: thermal bonding nonwoven fabric is to point to in fiber nets with fibrous or powder ...

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

Industrial CNC, insert and custom tooling such as router bits, saw blades, boring bits, planer and jointer knives, shaper cutters, and cutterheads for the woodworking ...

White cement manufacture and history ... Burning Process. In principle, any type of kiln used for grey clinker production can also be used for white.

Cage — In a mine shaft, the device, similar to an elevator car, that is used for hoisting personnel and materials. Calorific value — The quantity of heat that can ...

Even more » Account Options. Sign in; Search settings

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

However, at this time, even heavy industrial construction was still dominated by brick masonry, and earlier types of cement were already wellestablished in this market.

8 AU : IPRM 2007 : SectIon 8 : conSUMAbleS 441 WARnInG Welding can give rise to electric shock, excessive noise, eye and skin burns due to the arc rays, and a ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

China Mill Machine manufacturers Select 2017 high quality Mill Machine products in best price from certified Chinese Automatic Machine manufacturers, Mill Equipment ...

How is cement manufactured? Learn cement manufacturing process thoroughly.

WhatsApp)

WhatsApp)