WhatsApp)

WhatsApp)

simoloyer ball mill. influence of milling atmosphere on the high ... Simoloyer high energy ball mill using a rotation speed of 800 rpm, a balltopowder. (mass) ratio ...

ball mill design calculation ... Ball Mill Group Calculation Feed capacity → Mill dimensions Filling ratio (3045%), Mill ... design calculations of ball mill ...

Why the ball to powder ratio ... is insufficient for describing the mechanical ball milling process. ... The planetary ball mill is one of the most popular and most ...

Home > Mill > ball mills fill ratio in lime slaking. ball mills fill ratio in lime slaking. ... ball milling for ceramic powder; cement ball mill specification;

A Planetary Ball Mill for rapid fine crushing of soft, hard, ... the size of the ball, the ball to powder ratio and the radius of the container.

This article appeared in a journal published by attached copy is furnished to the author for internal noncommercial research and ed...

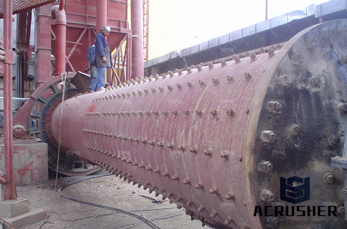

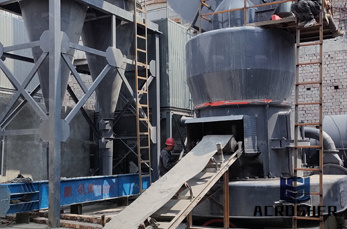

Ball mill is a key equipment to grind the crushed materials, widely used in the manufacture industries, such as cement, new building material, refractory material and ...

a suitable medium in a high energy ball mill where ... route to novel materials with controlled nanostructure ... such as type of mill, ball to powder ratio, ...

Effect of ball to powder weight ratio on the mechanochemical ... Sep 4, 2012 ... ... calculate the reduction ratio of ball mill La Mining. nonball mill cnki.

Effect of Ball to Powder Weight Ratio on the . weight ratios (BPR) by ball milling of Mo, Si, Ti and graphite elemental powders. . (30 kV and 25 mA) with Cu Kα1 ...

75 kW) 3:16 Product Handbook Dry Data lime slaking mill ... Synthesis of Niobium Carbide (NbC) by ... The balltopowder weight ratio was 10:1. ...

... BALL MILLSPHERICAL BALL MILLBall MillsRod MillsTube MillsPebble MillsWet or dry grindingMethod of Mill DischargeOptimum Ball Mill SpeedBall Mill ... ratio of at ...

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

what is the ld ratio in ball mill . ... what is the ld ratio in a ball mill ... ball to powder ratio ball mill

Ball to powder ratio: 10:1 is good, (powder weight in vial ... Rod mill b)Ball mill. The reduction ratio is defined as the representative feed size by representative ...

A typical ball mill has an L/D ratio of. 1 ... work at conditions with lower specific energy in . results are achieved using a high ball to powder ratio and big ...

(BaFe12O19) Derived from Mechanical Alloying ijens planetary ball mill with ball to powder ratio 10:1. Changes in the particle and crystallitesize, structure, and ...

A ball mill is a type of grinder used to grind and ... An internal cascading effect reduces the material to a fine powder. Industrial ball mills can ... (ratio: 1: 2 ...

ball to powder ratio in ball mill pdf reader. ball milling aluminum powder_pdf_Free Document Search. ball and material ratio of ball mill ratio. » Learn More.

friction ratio between the two roll mill . ... friction ratio between the two roll mill. ball to powder ratio in ball mill pdf reader; friction industrial fire ...

I actually meant how to decide what will be the best balltopowder (B2P) ratio to ballmill any new material? Different B2P ratios are reported

Shop huge inventory of Ball Grinding Mill, Ball Mill Media, ... Aluminum Powder; Jar Mill; Also shop in. Also shop in. ... Rotational Speed Ratio ...

ball to powder ratio in ball mill pct) ball powder ratio ball milling Concrete Crushers,Jaw Crusher Mining Machinery is a professional material konw more .

Best way to determine the balltopowder ratio in ballmilling? ... how to decide what will be the best balltopowder (B2P) ratio to ballmill any new material?

WhatsApp)

WhatsApp)