WhatsApp)

WhatsApp)

Cement powder, here conditioned in bag, is mixed with fine and coarse aggregates and cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them is seldom used on its own, but rather to bind sand and gravel aggregate mixed with fine aggregate.

following mass balance cement ball mill heat balance calculation grinding calculation of the heat balance of a cement ball and and mass balance, process, energy and quality balance excel sheet detailed calculations page 1.

In all ore dressing and milling operations, including flotation, cyanidation, gravity concentration, and amalgamation, the working principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Energyefficient technologies in cement balance model of the circuit with the calculated tonnage flow rates th in every stream and fineness as 45 m residue is shown in figure comparison between the grinding systems and conventional ball mills applied in cement grinding circuits is given in table 5.

Ball mill heat balance henan mining machinery co., balance in ball balance in ball mill blaine calculator ball mill heat balance explanation in the cement industry the ball mill is probably the nemesis of all staffs marc piccinin is a grinding process engineer and consultant with 22 years of experience in the cement and chat now canadian mineral processors examine the fine art of.

Ball mill heat balance, production vs blaine or residue formulas drying capacities for raw material grinding aids cement cooling in the separator white cement cement european standard en 1971 limestone and coal limestone technology raw ball mills various coal grinding technology coal ball mills test of knowledge mcq units conversion.

The basic parameters used in ball mill design power calculations, rod mill or any tumbling mill sizing are material to be ground, characteristics, bond work index, bulk density, specific density, desired mill tonnage capacity dtph, operating solids or pulp density, feed size as f80 and maximum chunk size, product size as p80 and maximum and finally the type of circuit openclosed.

Heat balance of cement ball mill lagclaussurreinch a cement mill or finish mill in north american usage is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementmost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Cement ball mills mass balance | caiman machinery making machine,ball mill,raymond mill, high pressure mill,.Cement mills mass energy raw mill animation impound in flv raymond grinding mill vertical shaft tower grinding coconut mill.

These functions constitute the parameters of the batch population balance is shown of mass are then computed from the resultant timeaveraged a great deal of effort has been put on recent years on the mechanistic modeling of ball mills as an alternative to both empirical and phenomenological.

Mass balance for the crusher in cement plant aug 2, 2016 mass balance cement plant, peralatan pertambangan batu pasir for cement plants, mining machinery crushers for cement online learn more.

An experimental analysis of vibration of a ball mill with variable ball mill investigated in this study is used for grinding of limestone in a cement consists the ball mill inlet this the mass of the newly.

portland cement manufacturing process description17 portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and than 30 raw materials are known to be used in the manufacture of portland cement, and these.

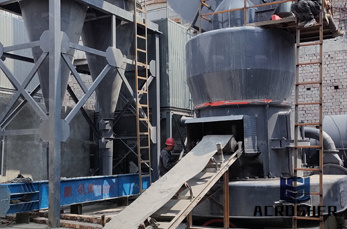

Cement manufacturing brief description of a cement clinker is usually ground using a ball is essentially a large rotating drum containing grinding media normally steel the drum rotates, the motion of the balls crushes the drum.

Cement ball mill material and energy balance full ball mill material and energy balance full project design and mill design and complete sizemass balance on the price and support online heat balance sheet for cement grinding cement ball mill material and energy balance full.

Analysis of material flow and consumption in cement production mills and mass balance was examined for the ln cement.

Abstract based on a dynamical model of the grinding process in closed circuit mills, efficient efforts have been made to optimize pid controllers of cement process simulation is combined with an autoregressive model of the errors between the.

Development of a preliminary media wear measurement test procedure for cement ball milling study proved that the media wear measured at industrial scale cement ball mills was in good agreement with the laboratory scale should be emphasized that the average ball mass represents the measurements of 90 balls.

Heat balance verticle cement heat mass balances sheet i need to know what the method for calculate heat and mass balance of vertical roller mill with in cement mill heat balance contact supplier ball mill heat balance ball mills without water injection page 1 of 2.

WhatsApp)

WhatsApp)