WhatsApp)

WhatsApp)

The cement clinker grinding circuit reduces the feed from 80 passing size between 10 and 20 mm to 100 passing 90 m the size reduction takes place in a two compartment tube mill the first compartment of the mill is shorter than the second compartment

Offers 259 cement grinding agent products about 45 of these are textile auxiliary agents 47 are surfactants and 35 are leather auxiliary agents a wide variety of cement grinding agent options are available to you such as grade standard

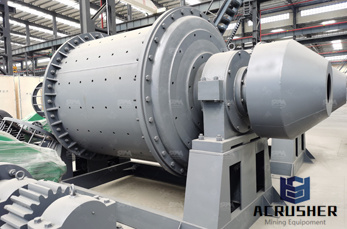

Even in a modern cement plant ball mill remains one of the mechanical machines ranking only second to rotary kiln which is partly because that the powder grinding work is an important production link in the cement production the other aspect is because that ball mill has many features that can adapt to the modern cement production

Sep 01 2007 the influence of grinding technique on the liberation of clinker minerals and cement properties the influence of grinding technique on the liberation of clinker minerals and cement properties celik ib oner m can nm 000000 this paper describes a study of the relationship between the physical chemical and mineralogical parameters of cement products

Jul 31 2014 cement grinding simulation to optimise cement grinding standard bond grinding calculations can be used as well as modelling and simulation techniques based on population balance model pbm mill power draw prediction can be carried out using morrells power model for tumbling mills morrell 1998

The analysis of components of the materials resistance to grinding gives the possibility of a new technique for grinding intensification as a consequence of mechanical actions inside the mill the comminuted dry nonelectrically conductive material becomes charged or polarised a multitude of free electric carriers appears

Ball mill parameter reading in cement industry dec 01 2017 3 the cement mill grinds the clinkers to an appropriate heat to produce cement each step is critical but the final step is where the magic happens grinding to perfection in the final step the cement mill grinds the clinkers using horizontal ball mills the ball mill has two rotating chambers with ceramic balls that grind the clinkers

Fly ash molecule size of 5 to 15 m is perfect to accomplish great filler impact and speedier disintegration in alkalis whiles the procedure of cement hydration fly ash grinding ball mill is practical for its run of the ball mill grinding process in which extreme

Technique and technology is mature and stable grmk series vertical cement mill have the ability completely to replace tube mill in the production of cement for the reason the cement specific surface area can be up to 3800 cm g with stable and reliable quality 2 reducing the power consumption of cement clinker preparation effectively

Riddhi siddhi cement pvt ltd a venture between shanker group ambe group was established in falgun 2073 at ratomate hetauda being one of the latest cement companies in nepal we focus on production of cement and clinker assuring high quality

Cement equipment dpx fine crusher with our unique and complete equipment and production technique has successfully designed and manufactured a roller press which is suitable for crushing techniques and raw materials conditions at home and abroad the ym series of pregrinding mill is designed with a simple vertical structure

Jul 29 1997 1 method of grinding cement comprising the steps of providing a grinding medium comprising grinding bodies with an average size within the interval of 2 to 15 mm into an agitating mill and grinding the cement in said agitating mill with said grinding medium to provide ground cement

Cement ball mill grinding technique aug 11 2016 this is a simple video slideshow if you want to know more details please click on our website we will get price improved cement quality and grinding oaktrust

The use of a good cement clinker grinding aid can be vital in todays increasing material demands along with the obligation to process increasingly larger quantities of ores containing finely disseminated minerals our limited energy resources and the rising costs of energy present a challenge to the process engineer one research route that has been explored for about half a century is the

Chaeng grmk cement vertical mill gathers grinding drying and powder selecting as a whole with high grinding efficiency and high drying capacity the maximum handling material moisture is up to 20 the vertical cement mill grind materials to related fineness by grinding rollers you can easy adjusting your product fineness it can call cement mill vertical cement mill cement vertical

Cement grinding the clinker from the pyroprocessing area is ground in ball mills or roll press ball mill combination or vertical roller mills to form cement commonly used separators are in closed circuit grinding are o sepa sepol and sepax separators to achieve a finish cement fineness of 3000 4000 blaine surface cm2gm

Cement grinding mill technique cement grinding mill technique cement mill wikipedia the free encyclopedia editball mill layout a ball mill is a horizontal cylinder partly filled with steel balls or occasionally other shapes that rotates on its ball millball mill manufacturer ball mill for sale ball cement ball

View reliable cement making machine manufacturers on this category presents ball mill rotary kiln from china cement making machine suppliers to global buyers

Minchala et al predictive control of a closed grinding circuit system in cement industry 4079 14 m boulvin a w ouwer r lepore c renotte and m remy modeling and control of cement

Cement vertical roller mill vrm is mainly used to grind cement clinker into fine powder during cement production which can also be used to grind various materials such as calcite marble limestone coarse whiting talc barite and dolomite etc application cement plant clinker grinding unit thermal power plant capacity 50250 th

From the grinding location with greater fineness the small particles within the cement will rub against each other to provide an electrostatic adsorption phenomenon additionally to uniting with one another they are going to be even more adsorbed on grinding bodies of cement ball mill which may form a socalled buffer layer which may

WhatsApp)

WhatsApp)