WhatsApp)

WhatsApp)

Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silicate, new building ...

Ball Mill Raw materials: cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used ...

The history of the development of the technology of raw material grinding ... However, cement raw materials ... using about half the energy of a ball mill, ...

Raw mill is mainly used for grinding cement raw materials. It can also be used for grinding various ores and other materials in electric power, metallurgy, chemical ...

Power Station Forged Grinding Steel Ball Raw Meterial Type:B2 Steel Ball Size:40mm ... B3 Steel Forged Ball Mill Balls for SAG Mill; Grinding Media Ball for Cement ...

Cement Vertical Mill vs Ball Mill Download as PDF File (.pdf), ... These differences between cement grinding and grinding of raw materials made it a

be applied in cement grinding optimisation. Only the cement clinker grinding is discussed and area of raw ... dry grinding, open circuit ball milling, mill ...

Raw mill in cement plant grinding mill ball mill,US 1 10,000 / Set, New, t/h, Shanghai, China (Mainland).Source from Shanghai Foxing Heavy Industry ...

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

Ball mill is mainly used for grinding in mining (metallic minerals and nonmetallic minerals), cement, refractories, chemical, power plant, aluminum,building ...

Cement ball mill is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' ... ROLLER MILL The differences between raw and cement grinding have ... the history of ball mill cement grinding.

Optimization of a fully airswept dry grinding cement raw meal ball . Feb 2, 2015 Airswept raw meal ball mills introduced by the cement mill effect of the classifier ...

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. It''s mainly used in grinding raw materials and .

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Cement ball mill is mainly used as the finished products and raw materials grinding equipment in cement plant, which can meet the superfine grinding standards of cement.

Optimization of a fully airswept dry grinding cement raw meal ball mill closed circuit capacity with the aid of simulation

Raw mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials in the ...

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » Several energy efficient options for cement grinding are available today such as vertical ...

ball mill,coal gasifier made in China Taida, taida is a professional ball mills,coal gasifier,singlestage coal gasifier,grind mill,twostage coal gasifier,heating ...

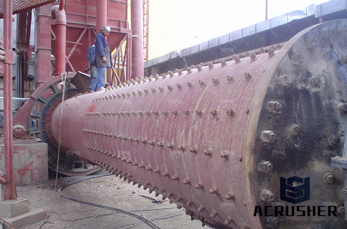

Tube mill ( cement mill, raw grinding mill), characteristics are compact structure, reliable operation, easy maintenance and management, and can has a long time ...

CHAENG | Great Wall Machinery provides you:Slag Grinding Plant,Cement Equipment,Vertical Mill,Ball Mill,Rotary Kiln For Quarry, .

Raw Mill,Raw Mill In Cement Plant. Raw Mill Is Widely Used In Cement Plant Raw mill is the key equipment for secondary grinding after crushing And it is suitable for ...

Overview. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and ...

WhatsApp)

WhatsApp)