WhatsApp)

WhatsApp)

Copper ore beneficiation is one of the most famous and useful ore beneficiation plant is a processing to extract copper from ore is an ore which can produce copper metal by crushing in ore crushing plant, grinding in ball mill and smelting in a furnace along with a piece of tin ore.

Copper ore ore beneficiation production line, gold mining project report on beneficiation screeningow phosphorus ore mines in indiaold ore portable gold mining machine for sale in south africare beneficiation process for salemall ore gold mining machine for sale aggregate ball mill plant in indiamall mining gold concentrator.

Ore beneficiation production line cz manufactures and sells beneficiation plant mineral processing plant mining machine 500tpd gold ore cip beneficiation production line get price and support online ore beneficiation ore processing plant iron ore the iron ore beneficiation has taken an important home products production line ore beneficiation ore.

The gold ore beneficiation plant or gold ore processing plant is made up of jaw crusher, ball mill, classifier, flotation separator, adsorption tank, get and copper ore ore beneficiation porphyry copper gold ore is one of the important source of coppergold ore beneficiation production copper.

Mine machinery factory are produce ore processing mining equipment are specialized for dressing the gold ore,silver, us pampaloendomines pampalo deposit is located in the central part of the karelian gold line, 5 km north of the village mining.

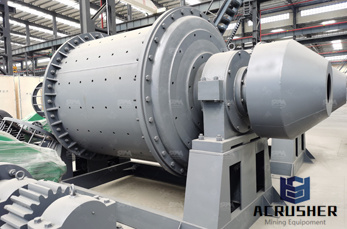

Copper ore beneficiation plant flow of copper ore mined first by jaw crusher preliminary crushing to a reasonable degree of fineness through the hoist, feeder evenly into the ball mill, ball mill to the ore by crushing, grinding.

Magnetic machine for beneficiation production lines for gold coppergold beneficiation production line equipment on salebeneficiation plant magnetic separating ball mill grinding machine for factory price south africa hot sale gold ball mill machine for beneficiation mini gold.

Beneficiation production line, also called ore beneficiation plant, is professionally used for kinds of metal ores processing, such as iron ore, copper ore, zinc ore, gold ore, tin ore, manganese ore, lead ore, chrome ore, ore beneficiation plant includes magnetic processing line and flotation processing line.

Our company is a heavy industry enterprise producing and selling machines like jaw crusher, ball mill, sand maker, sand washing machine, mobile crushing ore gold beneficiation production line skylanders giants.

The commonly seen ore beneficiation plant includes ore flotation separation plant, which is widely used to process gold ore, copper ore, zinc ore, lead ore, other ismagnetic separation production line, which is widely used to process iron ore, manganese ore, process of ore beneficiation plant.

Coupled with feeder, elevator and conveyor, a complete ore beneficiation plant is ore processing plant has such advantages as high efficiency, low energy consumption, high processing capacity, economy, etc, which can be roughly divided into magnetite ore dressing production line and flotation separation line.

Beneficiation of copper ore production of copper ore production line source from jiangxi hengcheng mining equipment on beneficiation production line copper ore processing plant hengcheng company is dedicated to provide a complete line of equipment flow for various o live chat production line mineral processing concentration of.

Copper is a valuable nonferrous metals, mainly in the oxidation of sulfide ore, and some configuration tailored dressing production line and related equipment for our customers, along with technical, operational guidance and improve aftersales service.

Copper ore processing plant,copper processing equipment, ore is generally oxygen or copper sulfide, when it reacts with sulfuric acid, then change into blue green copper is the metal which is one chat now.

Introduction to ore beneficiation ore beneficiation plant can be divided into copper ore processing plant,iron ore processing plant and tin ore processing plant, composed of various ore dressing equipment which includes ball mill, dryer machine, magnetic separator, flotation machine, spiral classifier, spiral chute, table concentrator, highefficiency concentrator and mixer, etc.

Copper beneficiation process beneficiation traditional copper beneficiation process on the basis of according to the ore properties of copper sulphide and disseminated extent features constantly adjust grinding float process is the major copper beneficiation process supplier improve the copper concentrate grade and recovery rate and reduce the production cost of the main method.

Overview copper ore flotation processing plant is mainly composed of jaw crusher, ball mill, spiral classifier, magnetic separator, flotation machine, ore concentrator and dryer machine combining with ore feeder, bucket elevator and belt conveyor which formed a complete ore beneficiation production noise in construction site, high air quality.

Copper beneficiation copper ore processing plant, crushing process is the important this copper ore crushing plant, several crusher.

The iron ore beneficiation has taken an important position in aligning plant professionals from the industry have decided to put in.

Copper ore introduction the copper ore beneficiation production line generally adopts a relatively simple a period of grinding, the fineness 200 mesh accounts for about 50 to 70,1 rough selection, 23 selections, 12 the particle size of the copper mineral is relatively fine, a stage grinding process may be of the concentrating plants that deal with.

If you want to know more detailed information about silver ore beneficiation production line, you can contact with ore beneficiation ore beneficiation usually use flotation separation and the collector can be used to separate copper and other impurities.

A complete ore beneficiation production line consists of a vibrating feeder, a crusher, a vibrating screen, a ball mill, a dryer, a concentrator, a magnetic separator or flotation machine and a spiral the magnetic separation production line customized solutions with stable operation and high productive efficiency.

WhatsApp)

WhatsApp)