WhatsApp)

WhatsApp)

4Axes Taig Micro Mill Computer Numerical Control (CNC) Conversion Last updated on Saturday, June 24, 2017 06:01:28 AM Eastern US Time Zone HOME. 4Axes CNC .

Tips for Getting the Best CNC Milling or Turning Surface Finish. CNC Milling Feeds and Speeds Cookbook

General Construction. Like all of the Sieg products I have used, this one is wellmade, starting with a heavy castiron base, on up through some sophisticated digital ...

Feb 26, 2015· If you''ve read my book "Dirt Cheap Survival Retreat" and or my blog post on selecting a grain mill then you already know, that I use the Corona hand ...

offers new and used industrial pumps for industry professionals worldwide. Industrial pumps of all sizes and condition are available..

Building a BrooksStent Cutter Grinder. Last Modified: 06 May 2016 01:20 MST Click to Enlarge . I eventually returned to my old notion of building a BrooksStent ...

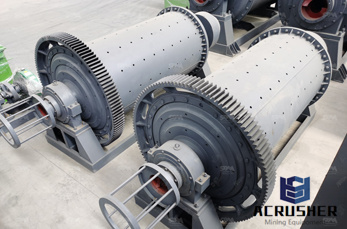

The point where the mill becomes a centrifuge is called the "Critical Speed", and ball mills usually operate at 65% to 75% of the critical speed. Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns.

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

Find all the manufacturers of gear reducers and contact them directly on DirectIndustry. Page 2

DRO PROS sells Newall and Easson digital readout systems starting at only 499! Call for all of your digital readout needs!

Are you carving large 3D contours or carvings ? You''ll want a ball nose bit that is appropriately sized for the level of detail in your model.

Grinding or particlesize reduction is a major function of feed manufacturing. Many feed mills pass all incoming ingredients through a grinder for several reasons:

The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, nc = rpm. But the mill is operated at a speed of 15 rpm.

Cement mill Wikipedia, the free encyclopedia . The critical speed (rpm) is given by: nC = /√d, where d is the internal diameter in metres.

Choosing a SAG Mill to Achieve Design Performance the correct power required to grind ore in a SAG mill, by developing ore .... trend is repeated in fullscale tests ...

Ball Mill Operating Speed Mechanical Operations Solved ... In a ball mill of diameter 2000 mm, 100 mm dia steel balls are being used for grinding.

Milton Roy manufactures controlledvolume metering pumps that deliver unsurpassed reliability and accuracy in critical chemical dosing applications.

Here is the senario, you friend JohnnyB is in the shop playing with his BP mill and a couple of new end mills. I''m still learning the most basic of things when it ...

t f c c Creative Circle 22 Long Acre Covent Garden London WC2E 9LY 020 7636 1223 © Creative Circle ×

Search Corporation company''s catalogues and technical brochures

The track will be your most important tool in getting the ball from one point to another on your sculpture. Sure, you could have the ball jump or bounce or be shot ...

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at ...

Drill Bits Unlimited: Your source for precision drill bits, engravers, end mills,router bits, HSS drills, center drills,

Pictures of the Taig Lathe, Mill Other Tools and Accessories . Here are pictures of the Taig Micro Lathe and Taig Milling Machine, pictures of my machines and other ...

WhatsApp)

WhatsApp)