WhatsApp)

WhatsApp)

Placer gold ore processing series heavy type european size mm, the fineness is production capacity processed materials limestone, calcite, barite, dolomite, potassium feldspar, read series vibrating feeder.

governing method for gold ore processing has been cyanide leaching since the late 19th century marsden and house, decades of active development of the process for various types of ores and concentrates, there are several different hydrometallurgical flowsheets for.

Dove laboratory will assay your ore samples rapidly and analyze your raw materials and recommend the most efficient processing plant according to the ore specifications, minerals composition, and ore assay results, and your project size and the geologic and topographic conditions of your mine.

The manganese ore processing plant crushing and sampling of manganese flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ead of both the primary and secondary mine run ore is dumped through a 10 grizzly into a coarse ore bin.

The company has the vision to become one of the top ten producers and exporters of gold in peru by 2020 through development and operation of small highgrade underground mines to supply ore to its efficient state of the art gold processing plant in the gold districts of peru.

A blockflow diagram of a typical cip plant for a nonrefractory gold ore is shown in figure i and table ii illustrate the capital and operating cost breakdowns for a typical south african gold figures are not a standard but reflect the nature of the ore and the design basis for a particular situation.

Mobile ore processing and beneficiation plant hot ore processing and beneficiation plant portable mills, and in particular, truck mills, are a most practical solution to this a relatively small investment a complete and efficient mill can be brought to.

Copper ore is an ore which can produce copper metal by crushing in gold ore concentration plant at the gold ore processing plant, gols should be extracted from the ore.

Xinhai epc provides services of sample test, mine design, equipment manufacture, clients, and solves the common problems in plant construction such as budget overrun, schedule delays, unqualified equipment, unclear recovery benefit, disputes of the manufacturers, and unclear responsibility of.

Concentrates from the cc are cleaned up on a wave table, to produce clean gold ready to be smelted and turned into a gold bar for concentrators efficiently recover fine recovery plant for ian for details, including how to source a new 13 tph centrifugal concentrator for under us10k there are larger.

Iron remove silica and alumina contamination to increase efficiencies in steel iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the fe value of the iron ore thereby increasing the efficiency of the steel production process.

Gold cil processing cil process is an efficient method of extracting and recovering gold from its process lowers the gold mining operation cost and increases gold recovery rate to a degree of is the first choice of modern gold mining and gold beneficiation plant.

2 view reliable mining thickener manufacturers on category presents thickener, gold concentrator, from china mining thickener suppliers to global buyers.

Mobile gold processing mobile gold processing plant in shanghai cathayphillips crushing equipment company produced is the most advanced and highefficient crushing screening system and its main technical parameters have reached or closed the same level the developed mobile gold processing plant have exported to vietnam, iran, india, chile, venezuela,.

About in 1987, we from a purely mechanical equipment manufacturers to now become a one of the hightech a century enterprise vision of the enterprise, sbm in the next seventy years, will continue to work hard, the pursuit of excellence, innovation, so that chinas national enterprises shine in the world.

Xinhai devotes to providing turnkey solution for mineral processing is an efficient design of extracting and recovering gold from its cil processing may, 2019.

At hengcheng, we provide more than just processing equipment, but constantly strive to assist you in achieving overall business is why when you partner with hengcheng, you dont just get a diversified product offering, but form a relationship based on product

Software and services for the mineral and metallurgical liberation measurement and analysis, ore characterization, fracture energy determination, breakage and selection function parameter determination, modsim, simulation software.

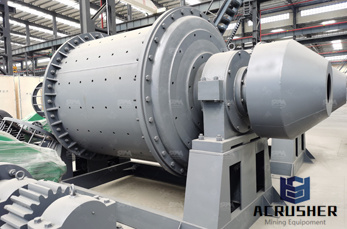

Onestop service for mineral processing than 70 kinds of dressing deep cone tank for chemical flotation and wemco gold ore ball mill.

Stage 1 of the ballarat goldfields plant has a number of unusual features designed to take advantage of the coarse gold ore plant is designed to run initially at a full capacity of 600,000 tonnes per annum tpa and is expandable well beyond that.

adds various tiers of ore processing for better ingot yields from raw tier use a specific machine to process the raw ore for direct ingots, dusts, clumps, shards or the product is processed by the machines of the previous tiers.

Research from the university of adelaide has found that certain nugget producing bacteria could be the key to developing more efficient methods of processing of gold ore.

Gold cil processing cil carbon in leach process is an efficient design of extracting and recovering gold from its cyaniding and carbon leaching crushed gold ore slurry simultaneously, cil process lower the gold mining operation cost and increase gold recovery rate to a degree of 99.

Canada, mineral processing pilot plant that will allow mining companies all over the world access to testing services and facilities that will develop more effective and efficient methods of processing pilot plant will support initiatives for processing minerals such as potash, rare earth minerals, gold, base.

WhatsApp)

WhatsApp)