WhatsApp)

WhatsApp)

Of all the methods of extracting gold processing it from its ore i used a few to evaluate two principal flowsheets in this case study the flowsheets utilized operations that involved flotation cyanidation and gravity concentration tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets this page offers a comparative review of gold recovery

Jan 18 2013 how to process gold ore how to process gold ore gold can be found in quartz veins and gold extraction wikipedia the free encyclopedia gold extraction or recovery from its ores may require a combination of comminution mineral processing hydrometallurgical and pyrometallurgical processes to be

For the first time ever gold processing can be done with a high level of confidence and safety from a very small jewelry business to medium scale refinery the process is simple and easy by using our refineit system all the user has to do is melt the gold in an ingot submerge the gold in the gold refining equipment we provide then wait

The two gold refining methods most commonly employed to derive pure gold are the miller process and the wohlwill process the miller process uses gaseous chlorine to extract impurities when gold is at melting point impurities separate into a layer on the surface of the molten purified gold

The hashing stage corresponding to metal extraction and recovery stages is a little more complex for gold ores as the optimal process flowsheet selection choice is heavily dependent on a good understanding of two fundamental geometallurgical parameters the gold mineralogical associations and the gold particle size and liberation

Refractory ore processing the common definition of refractory gold ores are those ores that do not allow the recovery of gold by standard gravity concentration or direct cyanide leaching one major category of refractory ores are gold values contained within the crystalline structure of sulfide minerals such as pyrite and arsenopyrite

Gold processing preparation of the ore for use in various products native gold is the most common mineral of gold accounting for about 80 percent of the metal in the earths crust it occasionally is found as nuggets as large as 12 millimetres 05 inch in diameter and on rare occasions

The main problem for individuals or small groups interested in hard rock gold deposits is the high capital costs both for the mining equipment to dig and remove the rock as well as the equipment to crush and process hard rock ore in order to extract the gold from its solid rock enclosure

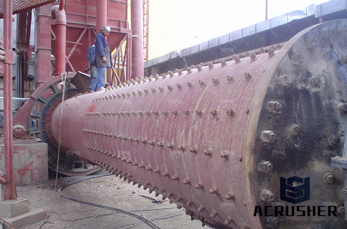

Gold ore mining processing plant gold ore processing plant is widely used in gold ore crushing and grinding process to resize and pulverize gold ores into 10mm to smaller than 1mm particles as gold ores vhn hardness is between 60 and 105 sbm design gold ore crushing plant and grinding machine that can process gold ore

The flotation process in general does not float free gold particles but is particularly effective when gold is associated with sulfide minerals such as pyrites in a typical pyrytic gold ore the gold is encapsulated within an iron sulfide crystal structure highly oxidized ores generally do not respond well to flotation

We offer and recommend our gold recovery training at our usa facility for no additional cost when purchasing our gold mining equipment large scale proven from the yukon through the rocky mountains and into the jungles we have designed and manufactured equipment plants systems processing 1500 tons of ore per hour

Gold processing solutions from multotec ensure your beneficiation plant is optimised for the lowest cost per ton with equipment covering each stage of the beneficiation process from rom stockpile to processed mineral and tailings multotec enables you to achieve your gold processing goals our equipment solutions for gold processing include

Savona equipment is your source for new and used mining equipment including underground mining and surface mining we have both rubber tire and rail equipment crushing plants underground and surface drilling milling equipment including jaw crushers cone crushers roll crushers flotation cells cyanidation equipment conveyors used pipe used fittings pumps and used electrical teck cable

I have my processing plant assembled and in production the equipment is very well made simple to operate and very durable their shaker table is the absolute best design on the equipment market today for concentrating ore and recovering free milling gold

All mobile plants have their own feed hopper classifier primary gold concentrator power system and water pump mounted on a trailer ready for work the reason behind mpp mstp processing plants is to offer oros clients affordable turnkey mining equipment for small medium scale mining

Gold mining equipment the gold mining equipment includes jaw crusher hammer crusher roller crusher impact crusher vertical crusher cone crusher ball mill vibrating screen spiral separator flotation machine mining agitation tank ore feeder concentrator mine hoist mining conveyor belt prewatering into a ball plate spiral chute beneficiation shaker washing machine and other

Gold cil process graphite mineral processing flowsheet fluorite flotation process pbzn ore dressing process magnetite separation production line gold flotation process acquaintance with us products more than 600 kinds of mining equipment

Gold ore prominer maintains a team of senior gold processing engineers with expertise and global experience these gold professionals are specifically in gold processing through various beneficiation technologies for gold ore of different characteristics such as flotation cyanide leaching gravity separation etc to achieve the processing plant of optimal and costefficient process designs

Gold ore processing project development and operations second edition brings together all the technical aspects relevant to modern gold ore processing offering a practical perspective that is vital to the successful and responsible development operation and closure of any gold ore processing operation this completely updated edition

Manufacturers and suppliers of innovative gold mining equipment for sale our industiral gold prospecting equipment includes sonic sluice boxes micron gold recovery units classifiers wash plants dredges recreational gold recovery plus used mining equipment for sale

Driven by a global team of process engineers and metallurgical specialists multotec designs builds manufactures installs and maintains equipment throughout the entire value chain of mineral processing plants across all commodity sectors from diamonds to coal gold iron ore platinum and phosphates

Ore processing flow the ore needs to be dry less the 15 moisture the air impact mill can be hand fed or fed by an optional feed hopperconveyor as the rock is processed through the air impact mill it discharges into a wetting cyclone attached to the mill the cyclone slurrys the milled ore and discharges to a closed feed trough

WhatsApp)

WhatsApp)