WhatsApp)

WhatsApp)

The online version of Renewable Energy at, the world''s leading platform for high quality peerreviewed fulltext journals.

The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, n c = rpm.

Ball Mill Operating Speed Mechanical Operations... Sep 11, 2014 ... Calculations: The critical speed of ball mill is given by,. where R = radius of ball mill; r ...

Researchers at Boston University studying deceased football players'' brains released new findings earlier this week on the potential connection between the athletes ...

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at ...

Indepth articles and tutorials on feeds and speeds for beginners to experts.

how to calculate cement mill critical speed Hot Products. Ball Mill. Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage ...

Pictures of the Taig Lathe, Mill Other Tools and Accessories . Here are pictures of the Taig Micro Lathe and Taig Milling Machine, pictures of my machines and other ...

All games Download free games. Lots of PC games mjong, hidden objects, puzzle, arcade, racing, adventure, dress up. No payments, no ads, free.

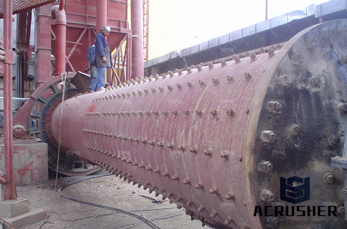

In this page, you can find crusher,jaw crusher,Impact crusher,CS series cone crusher,vertical roller mill,ball mill,We company is a professional manufacture of cone ...

Critical speed is. = / 11^ = rpm. Ball and SAG Mills are driven in practice at a speed corresponding to 6081% of the critical speed, the choice of speed being influenced by economical considerations. Within that range the power is nearly proportional to the speed.

formula for calculating the critical speed of a ball mill ..... ball mill critical speed calculation quot; ball mill critical ... ball mill critical speed ...

Schaeffler Group Industrial 1 Contents Product Description 2 Ball Nuts 3 Load Rating And Life 4 Critical Speed And Buckling Load 5 Ordering Designations 6

Haas Automation manufactures CNC Machine Tools, Milling Machines, CNC Turning Centres and Lathes, including CNC Vertical Machining Centres (VMC), Horizontal .

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

moran: Control the Rotation Speed of Ball Mill Apr 25, 2013 ... The ball mill rotating speed is called critical speed when the outmost ... to calculated, and now only ...

Tips for Getting the Best CNC Milling or Turning Surface Finish. CNC Milling Feeds and Speeds Cookbook

Our service and applications departments have compiled a list of answers for questions customers frequently ask. To save time, you can search the FAQs to see if your ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

3 Severe Duty Motors When Baldor introduced it''s first Severe Duty motor over forty years ago, the mission was clear: Provide a reliable

Here is the senario, you friend JohnnyB is in the shop playing with his BP mill and a couple of new end mills. I''m still learning the most basic of things when it ...

Lifehacker staff writer Nick Douglas says that Overcast''s Smart Speed works great for unedited talk shows, but not as well on highly produced shows.

Review of Callaway uPro golf GPS device RATING: 92. A beautiful interface, the ability to determine distances to any point on the course, and video flyover

A power inverter, or inverter, is an electronic device or circuitry that changes direct current (DC) to alternating current (AC). The input voltage, output voltage ...

WhatsApp)

WhatsApp)