WhatsApp)

WhatsApp)

CoProcessing Fuels and Raw Materials in Cement Manufacturing ... raw materials in the cement industry, ... regions where specific requirements have not yet

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

139 cement plants, 365 mini plants 40 players, the cement industry in India is the 2nd largest producer of cement globally. The Indian cement industry grew by

... of both his concrete and raw cement have shown that ... in the raw materials used to produce cement may cause ... requirement in production than ...

Ultratech Cement Limited is the largest cement company and among the leading producers of cement globally. It is also India''s largest manufacturer of white cement .

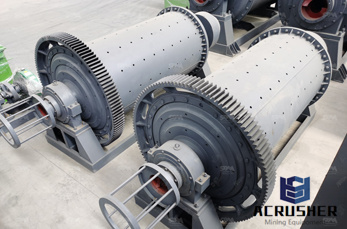

raw materials for cement production. ... reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals.

White cement manufacture and history ... Burning Process. In principle, any type of kiln used for grey clinker production can also be used for white.

Raw materials used in cement ... The most common raw rock types used in cement production ... they are blended in the proportions required to produce clinker ...

Manufacturer of Roofing Sheet Everest Fiber Cement Roofing Sheet, Everest Durasteel Roofing Sheet, Everest Steel Roofing Sheet and Everest AC Roofing Sheet .

Cement Production Process Three production steps are distinguished in the description of the production of cement: zPreparing raw materials: .

Grinding occurs at the beginning and the end of the cement making process. Approximately tonnes of raw materials are required to produce 1 tonne of finished

India is the second largest cement producer in the world. However, it is way behind China, where the capacity is more than five times larger. Cement is a lowvalue ...

react with water and cause the cement to set. The requirement for calcium is met by ... The UK cement industry has agreed to reduce its ... CEMENT RAW MATERIALS 2: ...

•Availability of funds 4 CASE STUDY Holtec had carried out a plant operations audit in a dry process cement plant operating at a capacity of about 3,350 tpd clinker.

Ammonia Production. In 1909 Fritz Haber established the conditions under which nitrogen, N 2 (g), and hydrogen, H 2 (g), would combine using medium temperature (~500 .

The cement industry faces a number of challenges that include depleting fossil fuel reserves, scarcity of raw materials, perpetually increasing demand for cements and ...

ASTM cement standards and concrete standards contain specifications and test methods to determine the properties of concrete, hydraulic cements, and aggregates.

The term brick refers to small units of building material, often made from fired clay and secured with mortar, a bonding agent comprising of cement, sand, and ...

Autoclaved aerated concrete (AAC), also known as autoclaved cellular concrete (ACC), autoclaved lightweight concrete (ALC), autoclaved concrete, cellular concrete ...

PMTZyklontechnik 3 Alternative fuel ALTERNATIVE FUELS IN THE CEMENT INDUSTRY 1 INTRODUCTION The production of Portland cement requires a high .

The world''s leading networking information sharing website for food safety practitioners.

Energy optimization in cement manufacturing ... ment and substituting fuels and raw materials to lower production ... effect the flow requirements.

The Portland cement productive technology is representative in the cement production, it use limestone and clay as raw materials, after crushing, dosing and ...

percentage of the energy cost in the total production cost. In the cement industry, ... Raw material process ... The Japanese cement production process is mostly ...

WhatsApp)

WhatsApp)