WhatsApp)

WhatsApp)

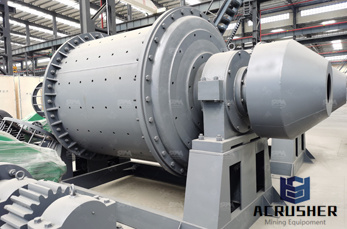

The operating principle of the ball mill consists of following steps in a continuously operating ball mill feed material fed through the central hole one of the caps into the drum and moves therealong being exposed by grinding media the material grinding occurs during impact falling grinding balls and abrasion the particles between the balls

Cement mill liners miter roller guard crown guard inlet chutes raw mill chutes raw mill ducts ducts for cement mill grit cone cones hoppers chutes name ball mill plate liner plate use ball mill main materials high manganese steel super high manganese steel high chromium medium chromium medium carbon alloy

Quality cement mill liners manufacturers exporter buy high cr steel stepped cement mill liners carbon steel material for ore mining from china manufacturer

Created specifically for erosion control containment and shelter applications concrete canvas cc products are part of a revolutionary class of new innovative materials called geosynthetic cementitious composite mats gccms cc is a flexible concrete filled fabric which provides a thin and durable concrete layer when hydrated

Optimization of the cement ball mill operation the first chamber coarsegrinds the feed material and prepares it for the second chamber the second chamber is the fine grinding chamber it is lined with classifyingtype mill shell liners and provided with finer ball charge classifying liners ensure that the ball charge is segregated along

Soilcement linings are constructed with mixtures of sandy soil cement and water which harden to a concretelike material the cement content should be minimum 28 of the soil by volume however larger cement contents are also used in general for the construction of soilcement linings following two methods are used drymix method

Protective liners and lining systems come in several forms loose or dropin liners and lining systems are prefabricated into a specific shape to conform to the surface of a specific product or component tile block or sectional liners and lining systems are cemented or bonded to a

Design of cement mill liners there are several types of cement mill liners feedendliners liftingliners classifying all have some features in common magotteaux determines the optimum design and alloy for cement mill liners to give the best mill protection this is done according to a variety of factors such as shell liner type rotation speed maximum ball diameter grinding

Cement mill liner bolts we hold expertise in manufacturing and supplying of high quality cement mill liner bolt that is known for superior performance accuracy reliability and durability we made these components from quality raw material sourced from reliable vendors of the market

Manufacturer of high chrome castings cement mill liners and diaphragms cement mill liners mill liners and haze mags blow bar offered by shilpa alloys private limited jaipur rajasthan

An overview of the selection and design of mill liners was published by which is the most predominant and aggressive failure mechanism for material loss in the cement industry mining operation

Apr 08 2009 high vibration of vertical mill for raw material hi everyone we have a problem with our rawmill type vertical mill of pfeiffer capacity 320 th is that rawmill is difficult for start because of high vibration sometime after starting 8 10 hours the rawmill suddenly vibrated very high and stopped the liner of table is worn quite much and same with roller tyres

Quality cement mill liner manufacturers exporter buy fmu29 high strength crmo alloy steel intermediate grate liners for cement mill 38 x 12 from china manufacturer

Abrasion is the most dominant factor in determining the working life of vertical mill grinding elements and the group supplies three types of alloy to cope with the different abrasion conditions in line with the trend towards ever larger mills the company can produce individual castings of

The roller grinding mill technology patented in 1928 and continuously developed since then has become synonymous with loesches pioneering engineering knowhow cement blast furnace slag cement raw material

A 15 mio ta cement plant is having a closed circuit ball mill for cement grinding the mill has been operating with satisfactory performance interms of system availability and output however power consumption was on higher side 31 system description mill rated capacity 150 th opc at 2800 blaine i chamber liners

Types of cement mill liners classifyingliners classifyingliners are the best form of cement mill liners to adapt the grinding charge to the feed materials granulometry while keeping a smooth material flow going they are efficient energy wise because of the constant optimum grinding charge

Figure 5 highlow wave ball mill liner materials the selection of the material of construction is a function of the application abrasivity of ore size of mill corrosion environment size of balls mill speed etc liner design and material of construction are integral and cannot be chosen in isolation

Our ability to combine different materials in the same mill using each material where it performs the best enables us to optimize your grinding process the lining material should be distributed in such a way that the thick portions protect the areas with high wear and the thinner portions are used on the areas with lower wear

Cement mill liners you can buy good quality cement mill liners we are cement mill liners distributor cement mill liners manufacturer from china market as2027 nicr4500 nihard durable cement grinding mill liner plates eb5061 material grade 1 martensitic cr mo alloysteelzg50cr5mozg60cr6mocr12mo hardnesshrc48 impact value

Cement tube mill internals shell liners liners made to last longer in cement manufacturing the group industries manufactures inlet discharge head first chamber and second chamber liners to provide optimum productivity and power consumption for all types of tube mill used in the cement industry

Subscribe to international cement review 12 issues of the leading cement industry magazine your choice of complimentary handbook plus unlimited access to news articles and hd videos 205 us 315 eur 260

Fabrication installation all liners are fabricated from urethane rubber 50 uses formliners can be reinforced with wood or other suitable material as specified or custom form panels or architectural concrete form liners can be fabricated specifically for your custom concrete form liner patterns and their subsequent decorative concrete formliners

WhatsApp)

WhatsApp)