WhatsApp)

WhatsApp)

Hammer milling parameters such as screen size blade selection and rotor speed can be optimized for each application depending on the equipment used the typical particle sizes that can be achieved with hammer mills is a d 50 between 150 m and 600 m hammer mills tend to yield less than 25 of particles below 150 m

Hammer mill the most appropriate style of hammer mill full circle screen hammer mills get their name because of the 300 degree coverage of the rotor nearly 50 more than traditional industrial gravity discharge hammer mills full circle screen traditional industrial this increased screen area provides more surface area for the material to

Design and evaluate of a small hammer mill selection initial and final in case a hammer comes in contact with a material hard to break at the first impact

Hammer mill high impact hammer mill capabilities creating finer particle sizes fully scalable to the d6a adaptable to specific material characteristics we offer a complete selection of atexapproved mills that meet the atex european union directive for

Optimizing hammer mill performance through screen selection and hammer design neal yancey christopher t wright tyler l westover background mechanical preprocessing which includes particlesize reduction and mechanical separation is one of the primary operations in the feedstock supply system for a lignocellulosic biorefinery it is the means

The basic principle of mill selection according to the feed properties is introduced in the following sections 51 hard materials when the hardness of the feed material is high hard material is used for the mill body construction as well as the grinding media or the impact speed must be reduced to minimize the wear of the mill

Jul 19 2018 the laboratory size hammer mill was fabricated from locally available materials for crushing of materials such as calcite dolomite limestone granite and

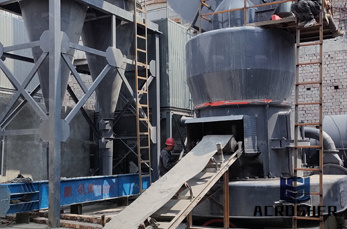

Classifier milling systems manufacturer of air classifier mills powder processing solutions cms has delivered innovative solutions milling technologies and mill systems to diversified industries globally for nearly 30 years hammer mill the cms hammer mill is a rugged highspeed industrial impact mill engineered to operate in

If the initial particle size of the sample is coarse it might be necessary to use two different pulverizer machines one for preliminary size reduction and one for fine grinding to achieve analytical fineness to choose suitable grinding tools is also part of the selection process for finding the right pulverizer for your material

Baby hippo hammer mill with air conveyor hippo hammer mills rapidly pulverize a wide range of materials from grain beans herbs and fibrous roots to minerals plastics glass bone and recyclables materials enter the milling chamber and are impacted by hammers rotating at high speed

Jaw plate material selection the impact of jaw plate wearable reason is mainly wearresistant material hardness and toughness material is too hard the material extrusion depth is shallow the material deformation is small the material for material shortrange sliding chisel cut is also small material toughness resistance to fracture ability can eliminate squeezing impact process

Key equipment hammer mill dfzk vertica the most economical hammermill for sawdust and small particles medium capacity to 3 tph no need for aspiration 20 lower electricity consumption than a comparable horizontal hammer mill significantly lower noise level 83db than comparable horizontal hammer mill 90db

End mill for smallscale carving for the desktop cnc carving project a ballnose 18 end mill is a good choice this type of end mill lets you get a smooth finish on a carving project because the round shape helps you avoid the stepping effect youd get from a flat profile tool

Xinxianghexie feed machienry manufacturing have been specialized in feed production line manufacture for many years our main products are various kinds of hammer mill also including pellet mill

Jun 14 2019 the key to successful equipment selection is to compare different size reduction methods for the best product at the lowest operating cost support services include system design and 24hour parts and service click here for related articles and news search for hammer mill manufacturers in our equipment guide

The study of project deals with the hammer mills employing a high speed rotating disc to which an n number of hammer bars are fixed and swung outwards by centrifugal al is fed in either at the top or at the centre and it is thrown out centrifugally and crushed between the hammer bars or against breaker plates fixed around the periphery of the cylindrical casing

Design fabrication and testing of a laboratory size hammer mill ajaka eo and adesina a department of mining engineering the selection of the right crushing equipment for a specific purpose is influenced by many factors some of which are downstream of the crushing plant mineral processing is a complex operation

The 911mpeic4000 is our high performance impact crusher or better known as hammer mill grinder specially engineered to outperform those runofthemill chain mills often falsely called hammer mills this crusher is effectively a small scale replica of industrial impactors in this rock crushing machine rock is projected against the inner cage and shatters by impact at 1750 rpm the ar450

Hammer mills mt baker mining and metals mt baker mining and metals hammer mills are industrial grade continuous duty machines hammers protective liners and screens are easily replaced at reasonable cost abrasive material grinding like granite or quartz ore requires regular daily hammer mill

For sale one 1 factory reconditioned 24 inch stone burr mill with material handling fan this stone burr mill is belt driven by a 15 hp 3 phase 60 hertz electric motor and includes the belt drive with belt guard and material handling fan belt driven from the stone burr mill magnetic motor starter available for

Hammer mill questions q what is a hammer mill a a hammer mill is a machine which through operates by impact action and will pulverize most dry freeflowing materials material fed into the hammer mill from the top falls into the grinding chamber the material is contacted by a series of hardened steel hammers rotating at high speed

Structure of hammer mill diagram for models 158 198 and 420 click here for measuring a screen millimeters vs click here for a 2mm 3mm and 4mm sample photo or here for a 6mm sample photo customer samples of material running through a hammer mill large photos of hammer mills page may load slow due to image size

The hammer and screen mill needs less air less ancillary equipment than the acm and is a lower cost option for pigment processing a ball mill grinds material by rotating a cylinder filled with media typically metallic or ceramic balls mixed with a continuous flow of feed and recycled material selection of the mill lining for soft

Aug 06 2014 a beginners guide to hammers and material of head depend on what youre hitting and why narrow heads deliver the entire force of the blow

WhatsApp)

WhatsApp)