WhatsApp)

WhatsApp)

Verical Roller Mill Vertical roller mill is MCC company to solve the industrial mill production is low, high energy consumption, technical difficulties, the European advanced technology absorption and mill design combined with the ...

SINGHASINI Manufacturer of Three / Five Roller Grinding Mill provide an automatic, dust free system for fine grinding of Soft to Hard Minerals up to 7 Moh''s Scale. The MILLING operation is performed on the principle of attrition and ...

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical raw mills are widely used in the concrete and mining fields, and are also used to process gypsum. These units can ...

As a key part of the vertical roller mill, it is easy for grinding roller to cause severe wear during the long grinding process because of the complex composition of the raw material which often contains some hard impurities such as ...

HPGR High pressure grinding roller In highpressure grinding roller comminution the feed material is exposed to very high pressure for a short time. ... Steel. ... Mill (grinding) Wikipedia, the free encyclopedia Grinding laws · ...

SBM Roller Mill,Mill,Grinding Mill for sale Shanghai Shibang Because of the centrifugal force, the materials move to the edge of grinding table from the centre .The materials are crushed by the grinding roller when by pass... Get Price

Vertical roller mill for cement grinding Finishing process Background In the cement grinding process, grinding system using the tube mill is widely applied for long year. Recently, especially from 1980s, grinding system using the ...

slide 1: Production Process As a key part of the vertical mill it is easy for grinding roller to cause severe wear during the long grinding process because of the complex composition of the raw material which often contains some hard ...

Product information: Raw material mill, also called raw meal mill, is important grinding equipment in cement production process. After being crushed, the raw meal enters the raw material mill. The raw meal is grinded into fine powder ...

Material Grinding Mill, Wholesale Various High Quality Material Grinding Mill Products from Global Material Grinding Mill Suppliers and Material Grinding Mill Factory,Importer,Exporter at MENU MENU ...

According to MIIT of China, instability of material bed, vibration in the mill mill, serious wear of grinding roller and grinding disc, and product quality issues can be encountered when VRMs are used for finish grinding, and further ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology 2 Introduction Around 110 years ago a Danish engineer, M. Davidsen, patented a ...

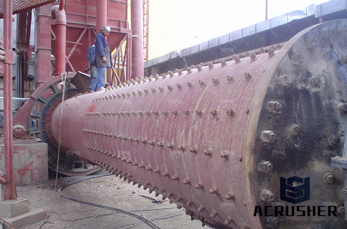

Ball Mill Manufacturer, Ball Mill For Sale,Grinding Mill ... Ball Mills are primarily used for fine grinding. Ball Mill is key equipment which repulverises the material after it is crushed. Ball Mill is widely used in powder ...

1 Item Vertical roller mill for raw materials Application p rocess Raw material process Background Grinding raw materials needs lots of energy. Tube mills had been used for grinding, but the energy efficiency level was lower.

Ball mill A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the ...

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and ...

slag grinding with loesche vertical roller. cal axis;. 2, 3, 4 or 6 grinding rollers of cement raw material a higher specific Vertical roller mills by Loesche for grinding slag and cement have been in operation for . The standards EN 196 ...

Tworoller mills Tworoller mills are the simplest variety, in which the material is crushed between two rollers before it continues on to its final destination. The spacing between these two rollers can be adjusted by the operator ...

Material Coal Mill Roller material, pew series is born with innovative significance. It is newly designed and improved by our experts on basis of their more than 20 years'''' crusher . » Learn More Polysius Roller Mills. For grinding 2.

The QUADROPOL® roller mill. The new mill generation, tailored to market requirements. The fundamental market demands on a cement raw material grinding plant are high throughput rates and drive power combined with small ...

The invention relates to a roller mill for grinding solid material such as cement raw materials and similar materials, said roller mill comprising a substantially horizontal grinding table and at least two rollers which are configured for ...

Vertical roller mills (VRM) can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding. According to MIIT, grinding media wear in a VRM will only ...

In a vertical roller mill, materials to be ground fall upon the center of a rotating grinding table. Centrifugal force causes the materials to spread out evenly towards the edge of the plate. As particles lying flatly on the plate reach a certain ...

grinding roller material ZCRUSHER grinding roller material Coal processing system Machine for ... Find the Right and the Top grinding roller material for your coal handling plant! » Learn More loesche mill grinding roller material ...

WhatsApp)

WhatsApp)