WhatsApp)

WhatsApp)

Iron ore mining process and iron ore and processing of iron ore involves coarse crushing and ore is beneficiated by crushing and then separating the iron from the gangue minerals through is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarse.

Iron ore mining process flow chart flowcharts pdf beneficiation iron ore mining process flow chart flowcharts iron ore mining process flow chart pdf iron ore mining process flow chart a flow chart shows sequential steps in a task or are many different smartart layouts that you can use to illustrate the steps in a process, including layouts that can contain pictures.

The ore is loaded into a blast furnace along with measured quantities of coke and combustion air is supplied to the furnace and some form of fuel used to raise the iron is reduced from the ore by carbon in the coke, the limestone aiding slag separation from the molten slag and molten iron are tapped off from the bottom of the furnace, the slag being.

The 100 owned marillana iron ore project marillana or the project is brockmans flagship project located in the hamersley iron province, within the pilbara region of western australia, approximately 100 km northwest of the township of project is located within mining lease m471414.

World resources are estimated to be greater than 800 billion tons of crude ore containing more than 230 billion tons of only source of primary iron is iron ore, but before all that iron ore can be turned into steel, it must go through the sintering is the primary feed material for making iron and steel in a blast furnace.

In addition to mined iron ore, other sources of iron, such as flue dust collected from blast furnaces, or the dust produced at mine sites, is also frequently pelletized so it can be utilized, as opposed to disposed pelletizing production of iron ore pellets from fines to finished product can differ based on a variety of.

Magnetite ore fe3o4 is a ferromagnetic mineral commonly used in magnetic separation coal washing washing using magnetite is used to remove contamination from runofmine rom coal, which usually contains rocks, middlings, used consumables and other contamination introduced by the mining process.

offers 2,535 iron ore mining process 4 of these are other mining machines, 1 are other food processing wide variety of iron ore mining process options are available to you, such as free samples.

The iron ore that is blasted is stacked and loaded upon large dumpers to be moved to the blast furnaces for smelting are made for the process of iron ore mining involves creation of benches that are used for the purpose of drilling, blasting, and finally the transportation of the iron ore to the crushing plant.

Iocs production process begins in the mine with drilling and crude ore is loaded into trucks, which dump the material into the loading pockets or into the inpit crusher located in the luce pit.

Iron ore is unrefined player with a mining level of 15 or higher can mine iron ore from iron rocks found in various mines, granting 35 mining experience for each ore takes seconds 9 game ticks for each ore to respawn within an iron level players often train.

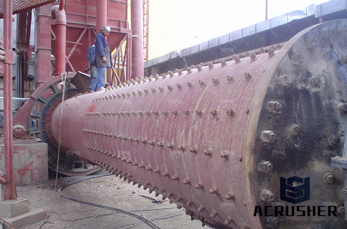

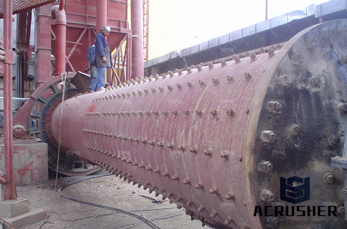

Mining iron ore jaw crusher is used for primary crushers and secondary crushers for crushing all kinds of minerals and rocks with compressive strength less than 320 are two types of jaw crushercoarse jaw crusher and fine jaw more.

Malvern panalytical solutions monitor the complete iron ore mining processes from the direct analysis on the conveyor belt early in the process towards laboratory analysis and complete automated quality the entire manufacturing process, from the iron ore to steel, malvern panalytical is the partner for exploration geologists and mine planners as well as for geometallurgists.

Iron ore wikipedia, the free encyclopedia iron ore mining methods vary by the type of ore being, and the gangue is separated during the beneficiation process and is removed as tailings.

Iron ore is an important raw material for iron and steel production crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron from natural minerals iron is the mineral aggregates that contain iron or iron compounds which can be used process of iron ore.

Miferma mines de fer de mauritanie was created in 1952 to exploit iron ore deposits in the kedia didjil area of northern mining centre was constructed at zouerate together with port facilities at nouadhibou on the atlantic coast, both with power plants and linked by a 700km railway.

Iron ore mining is one of the major industry of karnataka state in district alone in karnataka houses about 60 mines and produces over 40 million tons of iron ore per was a major customer and of the 40 million tonnes iron ore produced in bellary, 30 million tonnes was exported to china.

Mining of iron ore is a highly capital and energyintensive cycle assessment lca of the mining and mineral processing of iron ore in australia was carried out in this chapter.

Iron mining and processing in south africa resour ce pa ck iron mining and processing in south africa source kumba iron ore, university of cape town idyunivesithi yasekapa universiteit van kaapstad road construction concrete manufacture crushing open pit mining is used to excavate iron ore that is close to the surface.

The method does not use water to process iron ore, instead it transforms mining tailings with low iron content and no commercial value into high iron content and low contaminants, making.

The process of mining lowgrade iron ore, or taconite, requires massive industrial mining equipment, expansive mines, and a skilled labor pool are all of the equipment includes diamondbit rotary drills, hydraulic shovels and loaders, waterwagons, production trucks and heavy duty conveyors.

The chinese import price of 62 fe content ore fell by on friday to per dry metric tonne according to fastmarkets , after peaking earlier this week just shy of 126 a tonne, the.

Iron ore beneficiation is a multistage process that raw iron ore undergoes to purify it prior to the process of smelting, which involves melting the ore to remove the metal process of iron ore beneficiation has two complementary goal.

In 1975, iron ore production was 98 mt which rose to 858 mt in 2016, a 756 ore edr has increased 179 over the same time period 17 800 mt in 1975 to 49 588 mt in 2016 and total resources of iron ore edr subeconomic inferred have increased from 35 000 mt in 1976 to 152 083 mt in 2016, an increase of 335.

WhatsApp)

WhatsApp)