WhatsApp)

WhatsApp)

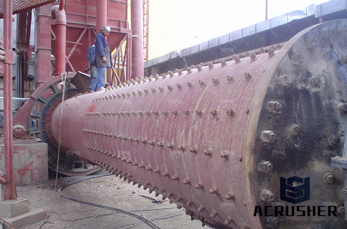

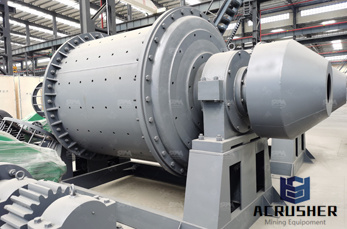

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls mounted on a metallic frame such that it can be rotated along its longitudinal balls which could be of different diameter occupy 30 50 of the mill volume and its size depends on the feed and mill size.

Hydraulic system vertical roller mill operation working principle of the hydraulic system vertical roller mill the hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts.

Roller mill is the most common device for crushing malt and grain into grist in preparation for the mills differ by the number of tandem operating rollers and by the treatment of the malt or grain prior to and during the milling is dry milling, conditioned dry milling.

Vertical roller mill operating system the vertical roller mill vrm is firmly established in cement plants all over the biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioning.

Customize your mill by choosing between six models, various roller diameters, roller lengths, and roller model is for you the new 80e plus experience our most advanced three roll smarter, safer and mill delivers faster dispersing results with realtime process analysis to make adjustments on the go.

Described is a roller mill 1 for grinding particulate material, such as cement raw materials, cement clinker and similar materials, said roller mill comprising a substantially horizontal grinding table 3, at least one therewith interactively operating roller 4 which is configured for rotation about a roller shaft 6 through the use of a.

Brochures here you can browse and find all our available technical brochures, and filter your search by solutions all solutions alternative fuels automation cement blast furnace slag cement raw material classifier coal and minerals customer service sales industrial minerals iron steel mining power industry services loesche america.

Within the scope of the study ore grinding performance of the vertical roller mill was investigated with mobile pilot this context, chalcopyrite ore of a plant having rod and ball milling circuit was ground under different operating modes, air swept and overflow, and process conditions, then samples were collected around the system.

Bamawm roller mills specialises in the manufacture of grain roller mills, grain augers, silo lid openers, feeding bamawm roller mills we are a family run business operating in victoria, australia since roller mills professionalism and product quality are paramount to our company and client satisfaction is our ultimate goal.

Hpgr or highpressure grinding rolls have made broad advances into nonferrous metal technology is now widely viewed as a primary milling alternative, and there arc a number of large installations commissioned in recent these developments, an hpgr based circuit configuration would often be the base case for certain ore types, such as very hard, abrasive ores.

The central control syste is capable of monitoring the operating conditions of the mill system, such as the mill vibration, grinding roller pressure, oil temperature, and mill setting can avoid personnel caused damage to the service life of the vertical roller mill.

Raymond mill is also called raymond roller mill, raymond pulverizer and raymond powder grinding mill is mainly used in powder making plant or powder grinder principle of raymond roller mill materials are firstly crushed by jaw crusher.

Roller mill pulverizing crusher is the industry leader in roller mill design, particularly due to their centrifugal force to grind material while maintaining lowoperating williams roller mill pulverizing machines feature easily replaceable wear parts and automated process controls.

Our bestinclass ok mill is a globally successful vertical roller mill solution for grinding raw material, cement and cuttingedge design features consistently deliver the highest quality products with the greatest efficiency.

For coarse reduction of grain, a roller mill may have a significant advantage perhaps as high as 85 percent over a hammermill in terms of throughputkwh of cereal grains processed to typical sizes 600 to 900 microns for the feed industry, the advantage is about 30 to 50 percent.

Pin mill is a kind of milling equipment that can break up cellular materials selectively without damaging the starch consists of two horizontal steel plates with vertical projections arranged in concentric circles on opposing faces and becomes more closely spaced towards the mill.

The fundamental market demands on a cement raw material grinding plant are high throughput rates and drive power combined with small construction size and high are precisely the performance characteristics of the new roller mill generation from reports now about operating experiences with the latest mill version.

In 1906, the first raymond mill appeared at the curt von grueber machinery factory in the grinding force of the raymond coal grinding roller was limited by the diameter and speed of the roller, the mill was only suitable for soft and and easy to grind coal materials.

Canada saintgermaindegrantham qubec j0c 1k0 canada phone 1 819 usa tom, wi, 54660 phone 1 608 .

Because the rolls are the working surfaces of any roller mill, extra money spent here on quality will pay you back big options double roll drive recommended for use on maize, beans consists of a pair of gears can be ordered with the machine or can be very easily selffitted retrospectively.

Built with durable, heavygauge materials, farm king roller mills deliver topquality processed grain with minimum maintenance and low operating or crimped grain is an excellent way to increase the nutritional value of grain, making it easier for animals to.

Impact mill, also known as impact grinder, impact pulverizer, impact microizer,impact hammer mill, impact crusher, impact contains a wide variety of powder mill, such as vibration mill, hammer mill, rollerrolling mill, turbo mill, pin mill, wide cavity grinding, impact would occur when material is dropped into a chamber where it receives a pulverizing blow from a.

WhatsApp)

WhatsApp)