WhatsApp)

WhatsApp)

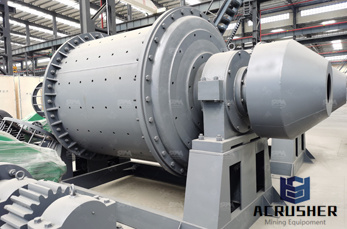

Ball mills account for the majority of all mills in cement plants and therefore the optimization of established ball mills implies high savings potentials.

CHANGSHA TIANCHUANG POWDER TECHNOLOGY CO., ... Lab Ball Mills; ... Lab Rapid Ball Mill; Lab Glove Box / Operation Box;

Planetary Ball Mills RETSCH''s innovative Planetary Ball Mills meet and exceed all requirements for fast and reproducible grinding down to the

operation and maintenance manual ball grinding machine. Home Milling machinery News operation and maintenance manual ball grinding machine grinding ball mill Gold ...

Ball mills and agitated media mills; Super Orion Ball Mill; Home. Hosokawa Alpine; ... Mills of 2 m in diameter therefore rotate in operation at about 23 ...

Ball Mills O nás. Ball mills Two chamber mills are used for grinding cement, slag and similar materials. They are typically arranged in a circuit with high effi ...

Variables in Ball Mill Operation. ... it''s just physics. The first problem will ball mills is that we cannot see what is occurring in the mill.

Ball mills designed for long life and minimum maintenance overflow ball mill sizes range from 5 ft. x 8 ft. with 75 ... Operation Ball mills operate either in ...

Operation of a Ball Mill « Wonder How To. How to Juggle the 4 ball Mill''s Mess This video shows how to do the 4 ball version of the Mill''s Mess juggling trick.

Planetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last few years the application of ...

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » Several energy efficient options for cement grinding are available today such as vertical ...

Operation Principle of Iron Ore Ball Mill Xinhai. The grinding operation of Iron ore ball mill has been very mature and its stable performance is why it has ...

Ball Mill Operation FREE BALL MILL OPERATION DOWNLOAD The best ebooks about Ball Mill Operation that you can get for free here by download this Ball Mill

What Is Ball Mill And Its Working Principle? The usage of ball mill and its technical data Ball mill is widely used for grinding ores and rocks in metal and nonmetal ...

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Ball mill operation and maintenance. To make the ball mill operate good, we must strictly abide by the operation and maintenance procedures. Before starting the ball ...

Charge behaviour and power consumption in ball mills: sensitivity to mill operating conditions, liner geometry and charge composition

Ball mill operation manual: ... Ball mills may not be the most efficient means of size ... For more operating parameters of ball mill information: ...

Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills.

What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling ... Types of Ball Mills

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

REALTIME OPTIMIZATION OF SAG MILLS USING GENETIC ALGORITHMS. operation. For SAG mills, the searching for the new ... is developed based on a first principles ...

Surfactantassisted ball milling: a novel route to novel materials with controlled nanostructure... 5 below this critical speed to keep the ball moving.

· Overflow Discharge Ball Mill in Operation in a RockPhosphate Processing Plant. For more videos related to Mineral Processing visit my YouTube channel ...

WhatsApp)

WhatsApp)