WhatsApp)

WhatsApp)

The influence of grinding conditions on the production of fine particles and the width of the particle size distribution produced during ball mill grinding was ...

Laboratory mills, used primarily for sample prep prior to analysis, use particle size reduction (comminution) to grind or homogenize wet, dry, hard, soft, elastic ...

ISAMILL FINE GRINDING TECHNOLOGY AND ITS INDUSTRIAL ... the power intensity of a ball mill is about 20 kW/m ... the particle size distributions from the feed to the ...

Type of Mill Media Size, in. Tip Speed, ft./sec. Ball mill ½ and ... 1. particle size reduction ... Keep in mind that no single mill will grind large particles to a ...

A ball mill is a type of grinder used to grind materials into extremely fine ... Particle size of the feed: For a mill to operate satisfactorily, ...

typical cement particle size out of clinker ball mill ... (Ball mill VRM) cement mills Particle size distribution ... mill will be used to grind the cement clinker ...

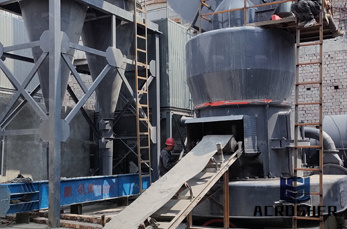

Cement clinker is usually ground using a cement ball mill. ... A cement mill is the equipment that used to grind the hard, ... uniform particle size;

Particle Size Reduction ... Why process at all? ... Roller mills used to grind in a feed mill are commonly referred to as a roller mill or roller mill grinder.

CEMENT GRINDING OPTIMISATION ... If the particle size distribution is known, ... The basis for modeling the twocompartment ball mill is the perfect mixing ball mill

One example is using a stirred ball mill such as an Attritor to perform the first stage of grinding and then achieving the final polishing grind ... Particle Size ...

MACSALAB Rod / Ball Mill ... The Ball/Rod mills are meant for producing fine particle size ... is on products that are soft and easy to grind and the ...

grind a gold ore in a ball mill ... flotation works best when applied to narrow size distributions. A 5 µm particle ... Improving Fines Recovery By Grinding Finer : ...

Ball mill grinding is one method of crushing ore to an appropriate size fraction. Specifically, ore is put into a large receptacle (a drum) and then it rotat...

Video embedded· Grind from a few milligrams to several kilograms into ... Particle Size; Dividing Feeding; Lab ... Fritsch Planetary Ball Mills .

cement grinding ball mill particle size reduction. ... To reduce process deviations and to stabilize the grind particle size analysis used to correct the.

I have been grinding materials or particle size reduction for over 30 years. I was introduced to making powder out of lead pigs in a ball mill at my fist job, and ...

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill ...

particle size for ball mill grind. Hardgrove grindability index (HGI),SlideShare. May 01, 2013· hardgrove grindability index (hgi) 1. presentation topichardgrove ...

Ball Mill RETSCH powerful grinding and homogenization. The RETSCH Mixer Mills grind and homogenize small sample volumes quickly and efficiently by impact and ...

Aug 15, 2016· Video embedded· FRITSCH Ball Mills grind dry or ... com cement grinding mill ball size Grinding Mill Ball Mill Cement fine particle size Ball mills are ...

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

The ball mill can grind various ores and other materials either wet or dry. ... The smaller the media particles, the smaller the particle size of the final product.

ball mill particle size [ 8431 Ratings ] The Gulin product line, consisting ... particle size for ball mill grind – Grinding Mill,Types of .

In materials processing a grinder is a machine for producing fine particle size reduction through attrition ... Ball mill A typical type of ... which grind material ...

WhatsApp)

WhatsApp)