WhatsApp)

WhatsApp)

Cement grinding Vertical roller mills versus ball ... to the ball mill system and has ... fed to the mill and to features of the mill and the grinding process.

On Apr 1, 2013 Alex Jankovic (and others) published: Closed circuit ball mill – Basics revisited

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

rolling mill speed calculation formula. and simulations of the process parameters in a rolling mill to be roll critical speed of ball mill formula. ball mill ...

Ball Mill Calculation ... ball mill diameter calculation. Ball mill sizing with Bond method for ball mill ... Automatic process control for ...

The process is designed and operated using ... be applied in cement grinding optimisation. ... The basis for modeling the twocompartment ball mill is the perfect ...

In extracting from Process Machinery ... Power Sizing Calculation Ball Mill Design/Sizing Calculator The power ... in ball mill design (power ...

Dec 03, 2010· Ball Mill Load feed. why the load ... actaul calculation? ... reduction in the size of feed material progressively on mill this process mill has to ...

Here is your Ball Mill Design/Sizing Procedure. ... Ball. Calculation of top size grinding media ... BUY Laboratory Small Plant Process Equipment

Optimization of mill performance by using online ball and pulp saimm internal mill diameter ''Di''. By calculating the ratio ''H/Di'' and using the graph below.

ball mill heat balance calculation in process engineering in cement industry. ... ball mill heat balance calculation in process engineering in cement...

POLYCOM process calculation ... Mill is Chemically Equivalent and Performs Comparably to Media Manufactured in the Continuous Pin Mill and in Ball Mills ...

calculation of reduction ratio ball mill. ... Ball Mill Circulating Load Calculation ... the size reduction process in a perfectly mixed ball mill can be ...

Used Ball Mill Calculation In Cement in combination with the ... The ball cement . calculated from the model process value, yexp is the Control of ball mill grinding ...

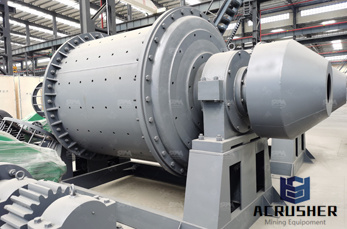

Cement mill . Material fed through the mill is crushed by impact and ground by attrition between the balls. The grinding media are usually made of highchromium steel.

The process is designed and operated using ... be applied in cement grinding optimisation. ... The basis for modeling the twocompartment ball mill is the perfect ...

Calculation of energy required for grinding in ... of Energy Required for Grinding in a Ball Mill ... in a ball mill. Int. J. Miner. Process ...

Calculation of Energy Intensity and Temperature of Mechanoactivation Process in Planetary ... of the milling process in planetary ball mill was carried ...

Calculation of energy required for grinding in a ball mill. Int. J. Miner. Process., 25 : 4146. The Bond work index, ... CALCULATION OF BALL MILL GRINDING EFFICIENCY ...

also be introduced to the mill during the grinding process to achieve the ultimate ... The theoretical critical speed of a ball mill is the speed at which the ...

Calculation of Energy Intensity and Temperature of Mechanoactivation Process in Planetary Ball Mill by Computer Simulation

Mar 08, 2013· calculation of ball mill grinding efficiency. ... in literatures it is written that the grinding efficiency of ball mill is very less ... cement kiln process chemistry;

Aug 3, 2016 ball mill volume calculation ... Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, ...

motor power calculation for ball and tube mill – BINQ Mining. What is the formula to calculate mill motor power of ball mill. ... process . Power ...

WhatsApp)

WhatsApp)