WhatsApp)

WhatsApp)

Claudius Peters manufacture materials handling and processing, from stockyard, pneumatic conveying, silo, clinker cooler, grinding mill and packing dispatch systems ...

Wet process kilns. The original rotary cement kilns were called ''wet process'' kilns. In their basic form they were relatively simple compared with modern developments.

1 This document does not necessarily represent the Commission''s official position TRAINING MANUAL FOR RISK ASSESSMENT IN THE CEMENT INDUSTRY

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

FL is a global engineering company supplying one source plants, systems and services to the cement and minerals industries.

Uttar Pradesh Rules ... Provided further that for a pressure vessel or plant in continuous process which ... Process flow diagram in detail indicating process ...

A major development during the second half of the nineteenth century was the use of ZnO in rubber to reduce vulcanization process times. Zinc oxide had been used as a ...

Module: 5 Lecture: 24 Cement industries Dr. N. K. Patel N P T E L 163 Comparison of dry process and wet process Criteria Dry process Wet process

What is Civil Engineering? What is Civil Engineering Technology? Civil Engineering is said to be the biggest and most...

1. Production process of cement In the times of Egypt and Greece, sintered and ground lime or plaster was used as cement for civil engineering and construction.

The leading website dedicated to feed mill machinery and equipment, Since 2003. Comprehensive news, articles, information, feed machinery ...

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the ...

White cement manufacture and history ... Burning Process. In principle, any type of kiln used for grey clinker production can also be used for white.

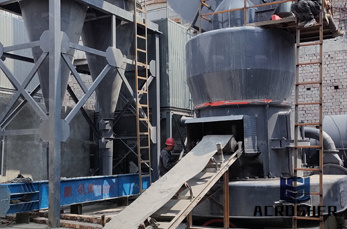

LM Vertical Grinding Mills. It has application in metallurgy, construction, and mining... Learn More; MTM Trapezium Grinder. MTM Medium Speed Trapezium grinder is a ...

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

Special Economic Zone at Villayat, District Bharuch, Gujarat Jubliant Infrastructure Limited

industrial case study: the cement industry calmac study id: final report prepared for pacific gas and electric company san francisco, california

calculators, engineering, mechanical, electrical, electronics, design, construction, manufacturing, consultant, layout, software, chemical, plastic, polymers

International Journal of Engineering Research and Applications (IJERA) is an open access online peer reviewed international journal that publishes research ..

Chalcopyrite ores are usually processed by means of hydrometallurgical or pyrometallurgical processes, but due to environmental aspects and the possibility of ...

Summary Statement . A comprehensive overview of health and safety in construction worldwide, including trades, typical hazards, methods of prevention, regulations ...

Complete package that includes: a) machine simulation teaches the student the setup and operation of CNC machines. b) CNC program simulation and gcode debugger ...

Figure 1 : Schematic diagram of the cement production process. Transition of specific thermal energy consumption for cement production. The specific thermal energy ...

Advantages of coal based thermal Power Plant. They can respond to rapidly changing loads without difficulty; A portion of the steam generated can be used as a process ...

WhatsApp)

WhatsApp)