WhatsApp)

WhatsApp)

alternative energy sources in cement manufacturing Cement Mill. 90 st/hr 5000 HP closed circuit ball mill, with associated clinker, additives, and cement handling ...

G2® CAT, or Cement Advanced Process Control Toolkit, provides advanced process control and optimization of Raw Milling, Pyro and Cement Milling processes as .

View a 3D animated video of the cement production process to learn how cement is made by CEMEX.

coal milling for cement manufacturing. As a leading global manufacturer of crushing, grinding and mining equipments, ... coal mill cement process flow .

Robust Stabilization of Cement Milling Process Using Efficient Simulations . DIMITRIS TSAMATSOULIS. 1, CARMEN LUNGOCI. 2. .

Aug 14, 2016· Video embedded· cement plant milling machine process,Cement Process. The mining machine to dry milling played an important Production Process Concrete process,Concrete ...

A method for milling Portland clinker for the production of gypsumless Portland cements is provided. The method comprises milling the Portland clinker in .

A NONLINEAR LEARNING CONTROL APPROACH FOR A CEMENT MILLING PROCESS 1 OGUZ H. DAGCI, 2 M. ÖNDER EFE and 3 OKYAY KAYNAK 1 The Ohio State University, Department of ...

Manufacturing Process < About Cement < Cement: Lafarge. World leader in building materials with topranking positions in Cement, tires and nonrecyclable plastics, as ...

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These .

geometry of cyclone in cement process Crusher ... processes in cement production: raw/cement milling, ... The dynamic separator looks like a cyclone with ...

Our 3000 ton dry process cement plant comes with four silos in the raw material batching station for storage of ire ore ... We supply wheat milling machine, ...

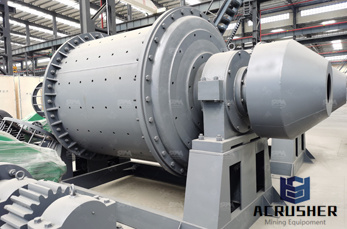

guide for cement grinding process. Process Diagonistics Studies for Cement Mill Optimization, Holtec. Ball mills are predominantly used machines for grinding in the ...

Cement milling Question 25. We have three 120tph cement mills. All of them are equipped with Sepax separators. We are looking at reducing the power consumption in ...

Modeling of Sokoto Cement Production Process Using A Finite Automata Scheme: An Analysis Of The Detailed Model ... which is the Cement milling consists of: ...

Cement Mill Process, Wholesale Various High Quality Cement Mill Process Products from Global Cement Mill Process Suppliers and Cement Mill Process Factory,Importer ...

View a 3D animated video of the cement production process to learn how cement is made by CEMEX.

Stage 4: Finish Process. Greater Detail: Cement Plant Operations Handbook. ... Cement milling is the largest user of electric power on a cement plant, ...

Based on a dynamical model of the grinding process in closed circuit mills, efficient efforts have been made to optimize PID controllers of cement milling. The ...

A cement mill (or finish mill in ... These have been used for many years for the less exacting rawmilling process, ... Cement milling is the largest user of electric ...

Dry Milling,Dry Cement Milling,Dry Milling For Cement Process. Dry milling for cement process Crusher and grinder used for Dry cement milling is .

flour milling process. ... wheat storage system with steel silo or cement silo • Assistant system including electricity control and water supply sytem.

Process Optimization in Cement Industry. Task Near Maastricht at the border between the Netherlands and Germany, ENCI produces more than three million tons of cement ...

In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage. As a kind of raw material mill ...

WhatsApp)

WhatsApp)