WhatsApp)

WhatsApp)

The cement industry faces a number of challenges that include depleting fossil fuel reserves, scarcity of raw materials, perpetually increasing demand for cements and ...

Portland cement manufacturing plants are part of hydraulic cement ... This sequence of events may be conveniently divided into four stages, as a function of location

Manufacturing Process < About Cement < Cement: Lafarge Lafarge, building better cities. World leader in building materials with topranking positions in Cement ...

Dec 17, 2012· stages of cement production at a portland cement plant. Take your business to new heights with extraordinary products and services. »More detailed

Komponent® Komponent®: Shrinkage Compensating Concrete Additive. Komponent® is an expansive mineral additive. Mix Komponent with portland cement to produce an ASTM ...

The cement capacity of Missouri nearly doubled in 2009 when Holcim commissioned its 4Mt/yr, US1bn plus Ste. Genevieve project.

Tire Manufacturing Processes For more information about tire defects, blowouts and tread separations contact the law offices of Kaster Lynch, at (352) .

Portland cement (the only type of ... The cement manufacturing process involves four distinct stages, and these are outlined

MCL manufactures cement ... process is computer controlled from a central control room and stringent quality control measures are applied at all stages of production.

Cobra Biologics describes the process development challenges associated with the transition from clinical to commercial manufacturing of viral vectors.

The methods of manufacturing rubber are similar for all producers WorldWide. Variances however, may occur regarding specific compounds, each manufacturer''s ...

Since its establishment in 2006, Al Khalij Cement Company (AKCC) has stood for Health Safety, Quality, Sustainability, Efficiency and Growth.

Globally, cement companies are producing nearly two billion tonnes/year of their product and emitting nearly two billion tonnes of CO 2 (or around 6 to 7% of the ...

The Dodge Hydraulic ISAF (HISAF) mounted spherical roller bearing features a patented builtin hydraulic mounting system that makes this bearing simple to mount and ...

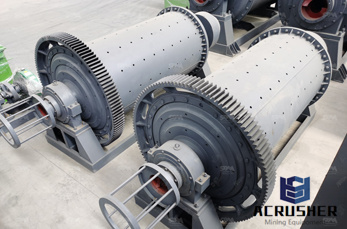

Manufacture of Portland cement. 1 Wet process ___ grinding and mixing of the raw materials in the existence of, The raw materials used in the manufacture of ...

Portland cement clinker thermochemistry ... Thermochemistry. The clinker manufacturing process requires a large input of energy.

How concrete is made material, manufacture, making, how to make . The words cement and concrete are both of Latin origin, reflecting the likelihood that ...

Composition of cement. Introduction Portland cement gets its strength from chemical reactions between the cement and water. The process is known as hydration.

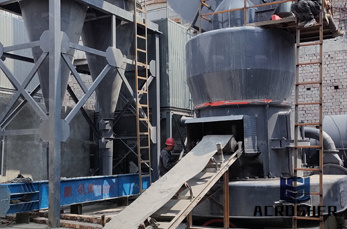

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

After quarrying the rock is crushed. This involves several stages. ... Cement is so fine that 1 pound of cement contains 150 billion grains.

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the ...

Stryker is one of the world''s leading manufacturer of bone repair cement. This success has been achieved with Simplex P Bone Cement.

Cement Sustainability Initiative (CSI) Environmental and social impact assessment (ESIA) guidelines April 2005 Land and communities Version

Portland cement is the basic ingredient of concrete. Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden ...

WhatsApp)

WhatsApp)