WhatsApp)

WhatsApp)

It is well known that the mill absorbed power depends on operating parameters other than ball level such as pulp density and liner configuration figure 2 shows that there is no linear relation between mill absorbed power and ball filling degree as indicated on the graph a

The effect of ball mill operating parameters on operating parameters mill speed mill charge ball size and wet grinding are the parameters which have been selected for the present study it is hoped that the analysis of the data acquired will allow insight as to which parameters will require a functional form if they were to be

Apr 29 2019 this study investigates the evolution of dimensional properties of grinding products namely the mass the surface area the length and the number of particle distributions with the energy input in a ball mill the size analysis of the mill products enables the calculation of the mass distribution of each material at predetermined size classes and then the determination of the other

Ball mill operational parameters effect of operating parameters in stirred ball mill grinding of coal one of the most energyefficient devices for producing micronized coal is the stirred ball mill in the present work various operating parameters such as stirring the operating principle of the ball mill

It is mentioned that the mill model does not take into consideration the operating conditions eg mill diameter ball filling volume and mill speed and a different unit model should be used to elucidate the ball filling effect on the grinding process for this purpose the austins scaledup unit model gmsu of modsim was used in this study

The effect of ball size diameter on milling performance open the aim of this project was to determine the effect of the ball diameter on the operating parameters of the mill which included the energy efficiency the power

The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency a mill geometry and speed bond 1954 observed grinding efficiency to be a function of ball mill diameter and established empirical relationships for recommended media size and mill speed that take this factor into account as well mills with different

In general both the performance parameters vary significantly 2040 with the mill operating variables however they do not vary in the same proportion the effect of mil speed ball load and mill diameter is relatively more pronounced for f the opposite is true for the effect of particle load and ball diameter on s and f

Sep 24 2018 combined effect of operating parameters on separation efficiency and kinetics of copper flotation ataall brami 1 yousef ghorbani orcid the sag mill products are then transferred to the two ball mills where the ore is ground to a level of p80 80 m lime and collectors z11 and ap407 are added to the ball mill feed as well

And the specific net mill power for a tumbling mill which is not affected by the operating parameters nomura s et al 1994 also confirmed this relationship two important factors should be determined before carrying out experiments in a mill namely the ball filling j and the powder filling f c j is the ball

The aim of this project was to determine the effect of the ball diameter on the operating parameters of the mill which included the energy efficiency the power requirement mill load critical speed as well as the size reduction of the mill charge it was thus required that these mentioned operating parameters be optimized by experimentally

In this work the relation between the change in mill output and cement fineness caused in the ball mill grinding process of composite cement with respect to different operating input parameters

Ball mill operation is often regarded as something of a mystery for several reasons ball milling is not an art its just physics the first problem will ball mills is that we cannot see what is occurring in the mill the other problem is that many of the independent variables are nonlinear or have paradoxical effects on the end results

Successively considered the equilibrium ball mixture was used to investigate the effect of ball size distribution on the selection function whereas the original equipment manufacturer recommended ball mixture was used to validate the model results show that with the six parameters abovementioned estimated the charge

It appears that the energy consumption of the stirred ball mill can be minimized through proper adjustment of the operating conditions a study of the effect of several key operating parameters indicates the following 1 for the type of stirred ball mill used in this investigation the energy input is used most efficiently at low stirring speeds

Ball mill designpower calculation the basic parameters used in ball mill design power calculations rod mill or any tumbling mill sizing are material to be ground characteristics bond work index bulk density specific density desired mill tonnage capacity dtph operating solids or pulp density feed size as f80 and maximum chunk size product size as p80 and maximum and

Jul 31 2015 significance of the effect of ball milling energy on rheological and thermal parameters of modified amaranth flour were evaluated by oneway anova significance level 005 with tukey posttest using prism 5 grappad software inc san diego ca usa

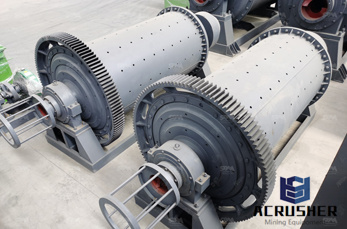

The operating principle of the ball mill consists of following steps in a continuously operating ball mill feed material fed through the central hole one of the caps into the drum and moves therealong being exposed by grinding media the material grinding occurs during impact falling grinding balls and abrasion the particles between the balls

Fig 2 laboratory ball mill and cylpebs used in the tests 222 the milling conditions the influences of operating parameters such as mill speed of nc ball filling ratio j powder filling ratio fc ball size distribution grinding aid dosage gmg and grinding time min were investigated in this study

Jun 19 2019 the results obtained from the study show that ballmill process can be successfully modeled in the main chocolate varieties for the particle size change and moisture removal which are among the main objectives of the use of this processing step therefore they have potential to use in the relevant production areas

Effect of the operating parameter and grinding media on the wear properties of lifter in ball mills zixin yin yuxing peng tongqing li zhencai zhu zhangfa yu and guiyi wu proceedings of the institution of mechanical engineers part j journal of engineering tribology 2019 92

Effect of ball mill parameters on performance vrm for clinker grinding which are more pregrinder in cement grinding circuits operating with ball mills to reduce the application of hpgr in cement grinding circuits and the effects of operational and design design parameters of the horomill are presented in table 3

Operating parameters of ball mill cgm grinding plant effect of ball mill parameters on performance ball milling parameter manipulation of sag mill operating parameters eg load ball charge get price ball mill design parameters sher usa

WhatsApp)

WhatsApp)