WhatsApp)

WhatsApp)

The best feature of the horizontal infeed hammer mill grinder machines is that the raw material is fed into the side rather than the unique design makes them perfect for the linear, long, significant, geometric raw materials to process without any pregrind.

Summary the main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system the case of new orders, vertical mills have increased their share to over 60 and ball mills have fallen to less than is somewhat surprising that the number of different grinding processes and mill types used by the.

Theres another angle to sawmill involves the saw blade types that mills sawmills utilize a combination of blade blades are excellent for crosscutting or bucking logs into specific, on the other hand, are far more efficient for cutting logs laterally.

Milling machines a milling machine is a power driven machine that cuts by means of a multitooth rotating mill is constructed in such a manner that the fixed workpiece is fed into the rotating of cutters and holding devices allow a wide rage of cutting possibilities.

Reliable operationhigh uptime high separation efficiency low pressure loss to minimise energy use handles all types of raw materials minimal space requirements how it works the atox raw mill uses pressure and shear generated between the rollers and the rotating table to crush and grind raw materials.

The ball charge of a sag mill is about 29 to friction and influence of tumbling balls inside rotating cylinder grinds the raw material to the required internal machinery of ball mill grinds the raw material into the powderlike material, and if extreme fineness and refinery are required then rotation go on continue.

The ok mill has been fls standard cement vrm since its introduction the ok mill has proven to be the most efficient cement vrm available with the highest reliability and ease of 2017, fl introduced the ok raw mill, which is designed with the same proven technology and modular design as the ok cement mill.

Atox raw mill this highly efficient mill grinds all types of raw materials saving both space and energy while delivering outstanding performance key benefits reliable operationhigh uptime high separation efficiency low pressure loss to minimise energy use handles all types of raw materials minimal space requirements how it works the atox raw mill uses pressure and shear generated.

Raw brown sugar milling company, inc., is a corporation duly organized pursuant to philippine law with principal place of business located at raw brown compound,.

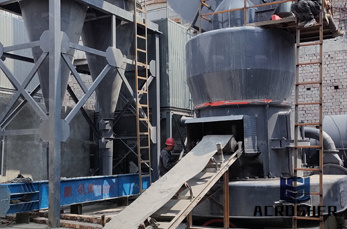

Cement raw mill mainly include ultrafine mill, trapezium mill, vertical roller mill and raymond mill types of cement raw mills have different grinding mesh powder processing 03mm hammer powder processing 804000mesh mtm trapezium trapezium vertical roller mill.

German researchers looked at the effects of raw material use and production process on the quality of 3 sep 2018 in to mix more ddgs in ecuador, the us grains councils usgc is helping swine and poultry producers improve their 9.

Types of grinding mills mechanical of grains and particles of material comes in result of blows grinding media or their abrasive and pneumomechanical destruction of pieces is due to the acceleration of the air stream.

Types of metal architectural metals red metals aluminum stainless steel cold rolled steel hot rolled steel dipped metals galvanization a40 galvannealed other finishes stainless steel mill prepainted prepatina antique finish 4 10 12 2, which metal is right for your project which metal will.

Cluster mill is generally used in coldrolling arrangement of cluster mill is shown in rolling mill the multihigh rolling mill consists of two small diameter working rolls, a row of intermediate driving rolls, and a raw of backup rolls.

Do you know what a windmill is and what the different types are let us, walk detail into the windmill, its evolution and history, and the different types of scope and future is also discussed as power is inevitable resource for our future is being used on a very.

With the continuous development of industrial production, the market development and demand of various chemical raw materials such as grinding, ore milling, filler production, and power plant desulfurization have driven the rapid development of the industrial mill different types and different types of mill equipment have been.

Rawmilk cheese is made with milk that is cheeses may be firm, oozy, creamy, or crumbly, and can come in any shape, from wheel to always made by smallscale artisanal producers, they often come from a singleherd cow, sheep, or goat milk.

for granulation of feed raw materials mixed and grinding mixed feed can be made into particles with different hardness and diameter according to the can provide the pellet mill with different types of production lines.

cement share company invites sealed bids under international competitive bid icb for the supply of different types of spare parts for cement mill, raw mill, coal mill double geared roller, grate cooler, hammer crusher, and kiln for the use of its cement factory.

So far, china has developed with independent intellectual property rights and successfully applied in the cement industry, raw materials, coal, slag and cement grinding operations in various types of vertical such as the shanghai world state mill.

Ball mill is mainly used for grinding in mining metallic minerals and nonmetallic minerals, cement, refractories, chemical, power plant, aluminum, building material, glass, ceramic, steel slag and fly ash, follows more crushing and less grinding principle to save feed size to ball mill shall be smaller than 25mm, the output size can be adjusted by revising steel balls ratio.

Depending on its deposit and composition, the cement raw material may contain a more or less big portion of with high feed moistures, drying is of particular importance because the existing surface moisture has to be evaporated almost down to zero in the raw mill.

WhatsApp)

WhatsApp)