WhatsApp)

WhatsApp)

An easytounderstand introduction to iron and steel, what they are, how they''re made, the various different types, and how we use them.

We provide information on mining,mining industry, mineral processing,gold,copper,fire assay, minerals,coal,engineering

Our Iron Ore product group is primarily focused on our worldclass iron ore operations in Western Australia. Products and uses. We''re the second largest supplier to ...

NEWS | 09 Aug 17:29; MetalX to invest in shredder, greenfield facility; Houston, 9 August (Argus) — Indianabased recycler MetalX plans to invest 35mn to build a ...

Today, iron and steel slag is used in many fields where its unique characteristics can be put to effective use. As a result of growing environmental awareness, iron ...

Information on mining taconite, a low grade iron ore, in Minnesota from the publication, Digging Into Minnesota''s Minerals by the Minnesota Department of Natural ...

A blast furnace is a special type of furnace for smelting iron from ore. Blast furnaces are very large. They can be up to 60 metres (200 ft) tall and 15 metres (49 ft ...

Iron ore is a chemical sedimentary rock that people have used as an important source of metal.

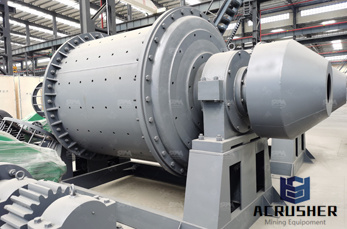

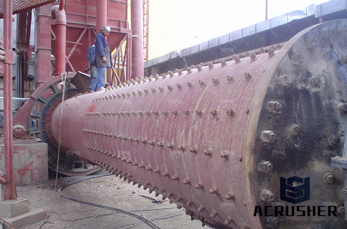

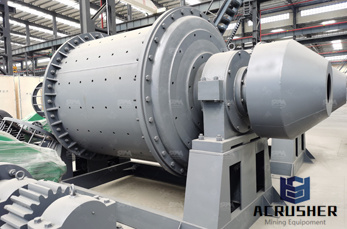

Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica ...

The purpose of a blast furnace is to chemically reduce and physically convert iron oxides into liquid iron called "hot metal". The blast furnace is a huge, steel ...

process of traditional iron smelting in eastern zambia and its possible impac on appropriate technology

What is the process of refining Iron ore? Iron ore refining process uses heat and another substance, so that oxygen molecule can bond to them and separate from iron.

Iron, which has the chemical symbol Fe, is an extremely useful metal and the most common element 0n the planet Earth. Here are some of the more common uses of iron .

Iron from meteorites was first used about 6000 years ago to make ornaments, weapons and tools. These days we use 20 times more iron (in the form of steel) than all ...

Bauxite from Little Rock, Arkansas, exhibiting a pisolitic structure and characteristic red iron staining. Specimen is approximately 4 inches (10 centimeters) across.

Slag is the glasslike byproduct left over after a desired metal has been separated (, smelted) from its raw ore. Slag is usually a mixture of metal oxides and ...

Slag definition, Also called cinder. the more or less completely fused and vitrified matter separated during the reduction of a metal from its ore. See more.

The slag comprises of granules of silico manganese denuded ore and the manganese which in the periodic table sits next to iron shares many of its properties

So your wife''s been a nasty slag all along? I knew she was trouble from the moment I first laid her. Lost your job huh? Damn man, that''s some cold hard slag.

164 SLAG IRON AND STEEL USES Different types of slags find different uses in the industry. The aircooled BF slag is crushed, screened and used mainly as road ...

Slag''s ain''t Slag''s. SLAG is a broad term covering all non metallic co products resulting from the separation of a metal from its ore, Its chemistry and morphology ...

Low CO2 Concrete. Stronger, Cleaner, Greener Concrete EF Technology® is a process that uses alternative cementitious materials that results in the reduction of ...

The USES and APPLICATIONS of VARIOUS CHEMICALS elements, compounds or mixtures. Uses of selectedexamples of Elements, compounds or Mixtures in alphabetical .

What is Iron Ore? Iron ores are rocks from which metallic iron can be extracted. It is one of the most abundant rock elements, constituting about 5% of the Earth''s ...

WhatsApp)

WhatsApp)