WhatsApp)

WhatsApp)

It is believed that milling machines date back to the 1700s although it is unclear exactly when they were first invented or by whom they are very similar to lathes so the earliest models were most likely just variations on the typical lathe machine milling machines became a separate class of tools sometime between 1814 and 1818

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder the cylindrical jar is used as a mill that would rotate the

After installing the r8 body in the milling machine spindle tool holders can be switched out in seconds to remove a tool holder depress the brass locking button and rotate the collar on the r8 body when a new tool holder is inserted a springloaded pin snaps the collar back into the locked position

This drill lathe mill combo will save space in small home shops and garages separate motors run the lathe and mill for longer machine life digital readouts help you get precise results read more about 3in1 milldrilllathe 3in1 milldrilllathe

Fabrication of aluminum flake powder by the wet ball milling of aluminum foil scraps and the effect of related factors were studied as foil thickness decreases from 60 to 65 mm mean size of powder milled for 30 h decreases from 107 to 17 mm it is impossible to mill

This is the recommended method for manual milling machines climb milling on the other hand feeds the workpiece in the same direction as the cutter rotation this is the preferred method for cnc milling milling is best applied as a secondary process to an already machined workpiece it helps to define features and serves as a finishing

The other is called hbempit process during which highenergy ball milling machine of spex8000m was applied with the milling frequency of 1720 rpm for 6 h for the ball milling treatment of precursor powders besides both insitu and exsitu pit processes were adopted for the fabrication

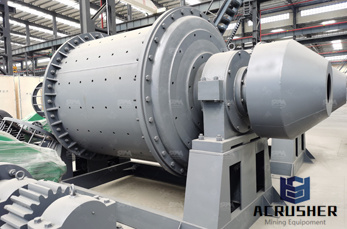

Ball mills steel ball mills lined ball mills particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800s the basic construction of a ball mill is a cylindrical container with journals at its axis

Get the best deals on bridgeport metalworking milling machines when you shop the largest online selection at free shipping on many items browse your favorite ball crank handle 58 bore milling machine bridgeport m1167 x y axis 3399 brand bridgeport 1590 shipping function milling 179 sold 2 new

Ball milling machine for nanoparticles fabriion fabrication of copper matrix composites reinforced with carbon in the first step a homogeneous mixture of copper nanoparticles and cnts was levelmixing followed by ball milling the mixture using a high energy ball mill

Fabrication of ball milling machine hardware parts of the machine are combined with fabricated as well as few commercially available productsain frame of the machine is fabricated using plain 8mm pvc sheet as per designesign file of each component is attached in appendix1ollowing table contains list of components required for cnc milling machine fabrication

Ball milling technique using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys in fact ball milling process is not new and dates back to more than 150 years it has been used in size comminutions of ore mineral dressing preparing talc powders and many

Milling machines can also be classified by the type of control that is used a manual milling machine requires the operator to control the motion of the cutter during the milling operation the operator adjusts the position of the cutter by using hand cranks that move the table saddle and knee

Design and fabrication of mini ball mill seminar design and fabrication of mini ball mill methodology typically the mini ball milling device consists of a cylindrical vessel mounted on an appropriate basis at both ends which allows rotation of the ves live chat fabrication of nanoparticles by milling or grinding

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls mounted on a metallic frame such that it can be rotated along its longitudinal axis the balls which could be of different diameter occupy 30 50 of the mill volume and its size depends on the feed and mill size

Application energy saving mining ball mill is a key equipment in beneficiation is widely used in ore dressing production line such as gold ore cooper ore magnetite ore antimony calcite kaolin mica clay bentonite etc ferrou metal or nonferrous metal materials

Milling machines require special safety precautions while being used these are in addition to those safety precautions described in chapter 1 do not make contact with the revolving cutter

This klutch mini milling machine is a cast iron milling machine that runs vibration free for smooth operation the 12 hp 110v variablespeed motor with a 2speed gearbox delivers 350 watt power milling head and column tilts to 45 left or right for added versatility etl listed

Video on fabrication of ball milling machine pdf ball mill ball mill mining machinery co ltd ball mill is widely used for the dry type or wet type grinding of all kinds of ores and video news

De sign and fabrication of mini ball mill design and fabrication of mini ball mill design and fabrication of mini ball mill the machine is categorized under the tumbling mill type of milling machine which the rotation cf the cylinder placed horizontally on the two parallel shafts placed side by side to each other

Fabrication of low cost 3axis cnc router andrai1 krishna2 khan3 and j balicdid research on the construction and evaluation of lowcost tablecnc milling machine2009 a ball bearing is a type of rollingelement bearing that uses balls to maintain the separation between

WhatsApp)

WhatsApp)