WhatsApp)

WhatsApp)

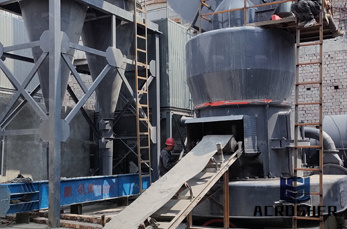

Manufacturing the cement kiln. Manufacturing the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its ...

THE MANUFACTURING PROCESS Portland cement is made by heating raw materials rich in oxides of silicon, calcium, ... Bay) and the wet process (used by Milburn).

Video embedded· How is cement manufactured? Learn cement manufacturing process thoroughly.

Wet process kilns. The original rotary cement kilns were called ''wet process'' kilns. In their basic form they were relatively simple compared with modern developments.

Cement the common binding material which has been used for several days on wards. There are many types of cements but portland cement is used commonly. The ...

wet process of cement. ... (Manufacturing Process), Portland cements are hydraulic cements composed primarily of hydraulic calcium silicates.

In wet process if chalk is used, it is finely broken up and dispersed it in water in a wash mill. Wash mill is a circular pit consisting of ...

Cement manufacturing process. Cement is the glue that holds the concrete together, ... There are three types of processes to form cement – the wet, ...

Jul 31, 2013· Video embedded· Now let us discuss wet process and dry process PROCESS:In the wet process, ... JK Lakshmi Cement Manufacturing Process Duration: 4:12.

Oct 29, 2012· These are two different processes of manufacturing wet process minerals are wet ground (by adding water) to form a slurry and then dried ...

Ash Grove Cement and Related Materials (Manufacturing Process), Portland cements are hydraulic cements composed primarily of hydraulic calcium silicates.

Cement manufacturing process | CEMBUREAU. In the second step cement is produced from cement clinker. The first step can be a dry, wet, semidry or semiwet process ...

Today we are going to start here one very important topic Cement manufacturing process and its selection with the help of this post. We will understand the ...

Cement Manufacturing Industry Description and Practices The preparation of cement involves mining; crushing, ... for the wet process.

manufacturing of cement. ... The three processes of manufacture are known as the wet, dry, and semi dry processes and are so termed when the raw ... Dry process ...

What are the differences between the wet and dry processes of a . The wet process of cement manufacturing involves adding water to finely crushed raw material, such ...

taken in the wet process of cement manufacturing, burn ing operation has the highest consumption of the total energy required for manufacturing, ranging from % .

Chapter 1 – Introduction to Cement Production. The wet process of fine grinding is the older process, having been used in Europe prior to the manufacture of cement ...

Cement manufacturing process | CEMBUREAU. What is cement? Cement is a fine powder which sets after a few hours when mixed with water, and then hardens in a few .

Portland Cement . Cement: ... Methods of cement manufacturing 1 Wet process ___ grinding and mixing of the raw materials in the existence of water.

manufacturing of cement. ... and semidry processes and are so termed when the raw materials are ground wet and fed to the kiln as a slurry, ... Wet process. cement ...

• What is Cement? • History • Overview of the Cement Manufacturing Process ... • Wet process easiest to control chemistry better

Manufacturing the cement kiln. Manufacturing the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its ...

Apr 19, 2016· What Concrete and Cement are made of and how BASF improves it with admixtures. Duration: 4:27. .

WhatsApp)

WhatsApp)