WhatsApp)

WhatsApp)

Web portal for buildingrelated information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

Table 1 below lists the five main chemical compounds in cement and their average percentages by weight. These compounds develop from limestone or lime and clay as a ...

Hannibal Plant Process Engineer Job Description. POSITION TITLE: Hannibal Plant Process Engineer REPORTS TO: Production Manager LOCATION: Hannibal Cement Plant

Dal mill dal machine, dal mill plant, mini dal mill, dal mill machinery, mini dall mill, mini dal mill plant, mini dal mill project, mini dal mill machinery cost ...

New York importer, distributor and fabricator of natural stone products and ceramic tiles.

Dry, semidry, semiwet and wet processes are the four main process routes that are used for the production of cement. Dry processes are considerably more energy ...

The main potential in reducing energy consumption and CO 2 emissions from cement/concrete production is in improvement of cement pyroprocessing.

I am assisting a waste to energy technology company to enter into the cement industry. The plant requires waste input such as municipal garbage, including ...

TECHNOLOGICAL UPGRADATION OF CHUNAR CEMENT GRINDING UNIT,, CHUNAR CEMENT FACTORY (A Unit of Jaiprakash Associates Ltd. India)

Cement All® If your concrete repairs, restoration and new construction projects call for a fastsetting, highstrength, nonshrink grout, use Rapid Set® Cement All®.

An online course exploring the quality control of cement manufacture, including the different quality control challenges faced by different cement factories around ...

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

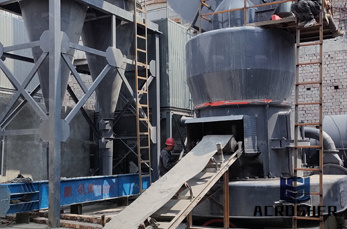

Crushing plant and grinding mill are widely used in the industry of mining, metallurgy, building materials, traffic, water conservancy and so on.

Maintenance Method For Critical Equipments Of Coal Handling Plant By:

You require it? We hire it. Plant Tool Hire, Sales Repairs. In business since 1974. Ireland''s number one independent tool hire outlet with over 40 years of ...

Raw materials for cement manufacture. The first step in the manufacture of portland cement is to combine a variety of raw ingredients so that the resulting ...

1 This document does not necessarily represent the Commission''s official position TRAINING MANUAL FOR RISK ASSESSMENT IN THE CEMENT INDUSTRY

Welcome to AKRO Multihire Providing tool and plant hire from Livingston, West Lothian, Scotland. Please browse our product range using the menu on the left.

Grinding Minerals design and manufacture a comprehensive line of grinding mills and entire grinding systems for mining, industrial minerals

Frank Key Hire offer plant hire services in Nottingham and beyond. View our extensive range of tool hire and submit your enquiry today through our website.

Loesche has provided a LM 56 3+3 CS vertical roller mill to Attock Cement Pakistan Ltd, for the grinding of cement clinker. The new mill will be used in the new line ...

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

Enter the name for this tabbed section: View MICCI Members by Business Sector

Manufacturing the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two.

WhatsApp)

WhatsApp)